- Home

- Bale Feeders

- Trailed Chainless Bale Processors

Trailed Chainless Bale Processors

Feed out literally any round or square bale of any forage type with the Hustler Chainless. Even the tightest hard center bales and frozen bales are no match for Chainless. The unique 3:1 feeding mechanism teases apart the bale making them go further without destroying nutrition which farmers are reporting saving up to 30% in feed costs compared to other bale feeders and processors! It’s self-loading with a patented total control loading system and carries two bales per load.

CHAINLESS TX205 / TH205 -Extreme Duty

Pull-type, Self-Loading, Chainless Round & Square Bale Feeder.

The Chainless trailed square and round bale feeders are self-loading, suitable for feeding out any bale, round or square, and it maximises feed use. Designed for medium to large operations. A Chainless feed out cart minimises feed waste by feeding out into narrow windrows to make the feed more accessible to animals and all but eliminate damage from hoof trampling, manure spoilage, and animals laying down on the feed. More efficient use of power, savings on machinery investment and faster bale feeding all add up to impressive fuel economy – made possible by the hydraulic drive system at the heart of every Hustler Chainless trailed bale processor.

5 reasons to choose a Chainless TH205

1. What's New?

- Excavator bushes & induction hardened pivots in loading system

- New indestructible puckboard table with 10 year warranty!

- Beefier chasis, platform, and loading system

- Increased lifting power

2. Feeds any Bale Type Shape or Size

The Chainless Trailed Bale Feeder is the most versatile Bale Feeder, it will feed out any bale round, square, tight, soft, short, long, dry and wet bales with ease.

3. Total Control 2 Loading System

This gives you total control overloading the bale. The simple, reliable and fool-proof single cylinder design of the Hustler loading system is safer than other loading systems and allows unwrapping of the bale above the feed cradle, reducing waste. The Hustler loading system can be reversed if the operator decides not to load that bale. It also has more support area for soft or square bales. The Chainless square and round Bale Feeder have more leverage, stronger design and larger 1.5-tonne (3,300 lb) capacity.

4. Easy Clean Hypaflo Wiper Panel

The newly developed wiper panel that clears the hay from the rotors better. It has a new quick release latching system for releasing the panel to clean out any hay.

5. 5 year warranty!

All backed with the Hustler 5-YEAR WARRANTY – another industry best for peace of mind, knowing there are backup and support that has been well proven for 60 years.

Key Features

Axial Rotor

The addition of a new Axial Rotor with centralising paddles keeps the bale positioned in the centre of the feeding chamber to minimise wastage and provide better grip on soft bales.

Ribbed Puckboard Platform

We’ve taken the puckboard used in ice hockey rinks, and put that ultra high density polyethylene on the platform floor. You won’t see any cracking or breaking with this. Being virtually indestructible, we’ve slapped a 10 year warranty on it.

Feed Control

Infinite variation in feed control, allows you to feed thick for cattle, thin for sheep to increase the palatability for your stock

Low Maintenance Drive

The entire drive system is now located at the rear, which allows better manoeuvrability. Bigger outboard bearing blocks are easily greased, larger shafts, automatic drive tensioners require no adjustments, and is designed to handle large 1.5-tonne bales (3,306 lb bales) (TX205). TE205 will handle up to 1-tonne (2,200 lb) bales.

Hypaflo Wiper Panel

The Easy Clean Hypaflow Wiper Panel minimises blockages and ensures that hay drops outside the wheel tracks to avoid being flattened into the mud. A quick release latch releases the wiper panel for easy cleaning.

Feed Guide

The clear, easy to read platform height guide shows starting positions for various bale types making it easier to use for all operators.

Protective Covers

Transmission covers protect against mud and debris getting at the heavy duty drive system which reduces maintenance.

Loadial

The new easier to read loading indicator makes loading any bale simple: line up the indicator to correct bale position, back in and load.

Diverter Valve

Our diverter valve is a safety feature and allows the Chainless to be used behind tractors with just 2 double acting remotes.

High Tensile Chassis

The Chainless round and square Bale Feeder is built to handle larger bales and has an impressive strength to weight ratio, achieved by using high tensile steel and larger section members. We’ve done our homework and put the steel where it’s needed, not in case it’s needed.

6-Stud Axles

Our 6-stud axles are the strongest on the market giving you longer life and more load capacity.

Massive Ground Clearance

The Chainless Bale Processor has more ground clearance allowing you to operate on rugged terrain. With the clean underside of the chassis there is nothing to damage or get snagged should you belly out.

Single Post Drawbar

The single post drawbar design has set the benchmark in feeder manoeuvrability and tighter turning. The drawbar is fitted with built-in road-legal safety chain mounts and an adjustable height towing eye.

Swiveling Towing Eye

The heavy-duty 12,000 kg (26,450 lb) rated forged towing eye has 50 mm (1.9 in) height adjustment to suit different size tractors. It rotates 360°, making feeding out on uneven terrain trouble-free.

Heavy Duty Parking Jack

New heavy-duty parking jack has an oversize mounting for a positive lock and safety. To allow for tighter turning, we’ve added an extra mount on top of the drawbar for stowing the jack.

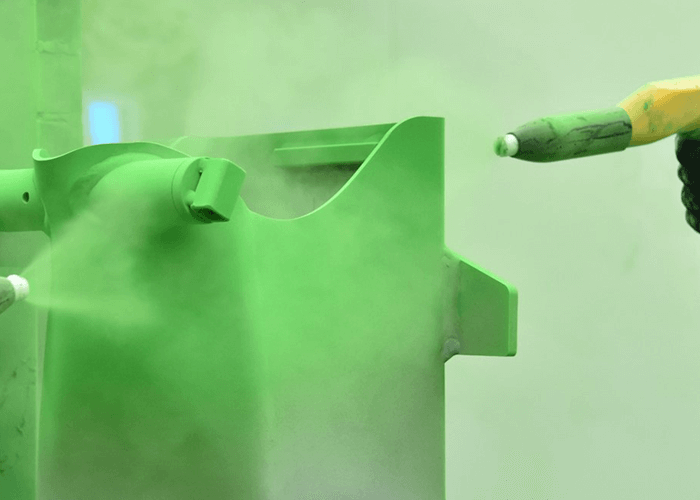

Sand Blasting & Armacote Finish

Hustlers’ unique oven-baked Armacote system is applied to a sandblasted finish ensuring long life, durability and a premium quality finish.

Stringbox

The Chainless TH205 is equipped with a large capacity stringbox which is very handy for stowing that bale wrap, fencing standards, and other items while you’re out and about.

Flotation Tyres

Now with larger tyres – larger diameter and wider tyres as standard. Providing improved floatation, cushioning, more ground clearance and the larger rolling diameter makes for smoother towing

Mudguards

Keeps your feed clean and dry when traveling between paddocks and reduces feed spoilage when operating in muddy conditions. Mudguards come optional (Standard for New Zealand).

Total Control Loading

The single hydraulic ram of Hustler’s Total Control 2 loading system makes loading faster and prevents bales from falling on the operator during unwrapping. A bigger tyne frame provides extra support for soft or square bales.

Quick Release Wiper

A quick-release latch releases the wiper panel for easy cleaning.

QRC Grips

Another industry first from Hustler! Quick coupling grips make connecting hoses easier and are labelled with “+” and “-” for easy coordination.

Rotor Teeth

Many hours of research and development have gone into the shape of the teeth to makes them clean easier, and have more aggression on tight bales. The Chainless has 5 teeth per rotor to provide extra grip on soft bales.

Hose Holder

Requested by farmers and unique to Hustler Bale Feeders, the drawbar mounted hose holder keeps the hydraulic hoses out of harm’s way, reducing chances of downtime. The Chainless hose holder has provisions to hold the hoses when the bale feeder is not in use.

Product Customiser

Select the product, then options and accessories to create your enquiry.

Chainless TH205 (extreme duty) Round & Square 2 Bale Feeder

Extras over and above TX205:

- Larger 400/60-R15.5 floatation wheels standard

- Puckboard platform floor – with 10-year warranty!

- Beefier rear loading system for heavier 5′ long bales

- Hardened steel excavator bushes and induction hardened pins in the loading system

- Stronger platform frame & drawbar

- Removable axles

- Side Chute now Standard

- Mudguards/Fenders (optional)

Chainless TX205 Round & Square 2 Bale Feeder

Limited Stock

Includes as standard equipment:

- Uprated 1.5 ton capacity

- Loading Tyne Position Indicator

- Quick Release Wiper Panel

- String Box

- Mudguards (optional in Australia)

- Standard with larger 11.5/80-R15.3 Wheel Assemblies

Options and Accessories

Extra Loading Tyne

Adding extra loading tynes to your trailed bale feeder is ideal for handling larger square bales that require additional support. As the tynes are a bolt-on option, you can retrofit them on any trailed models you use.

Side Chute 5ft (Chainless)

The Chainless Side Chute deflects the hay into a trough or bunk.

Even Feed Roller (5ft)

Optional even feed roller to help break up square bales.

Platform Extension For Square Bales (5ft)

Optional platform extension available for 8’ long square bales.

400/60-R15.5 Flotation Tyre & Wheel Assembly

Wide flotation tyres provide more flotation and stability in soggy conditions.

Mudguards / Fenders

Keep feed clean from contaminants when feeding in muddy conditions.

Extra Loading Tyne

Adding extra loading tynes to your trailed bale feeder is ideal for handling larger square bales that require additional support. As the tynes are a bolt-on option, you can retrofit them on any trailed models you use.

Side Chute 5ft (Chainless)

The Chainless Side Chute deflects the hay into a trough or bunk.

Platform Extension For Square Bales (4ft)

Optional platform extension available for 8’ long square bales.

400/60-R15.5 Flotation Tyre & Wheel Assembly

Wide flotation tyres provide more flotation and stability in soggy conditions.

Enquire now

Your selection

Selected product

Selected Options and Accessories

What you'll get

- Access to a dedicated Hustler expert

- No Obligation Quote

- Your Quote Within 24 Hours