The toughest, simplest and most versatile round bale feeding solution.

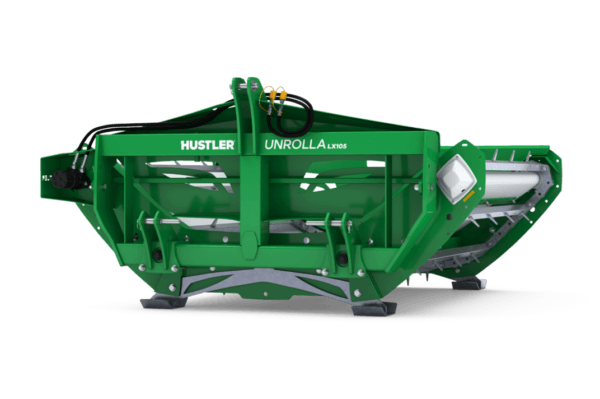

You simply won’t find another bale unroller with this level of versatility, ease of use, and time savings. Boasting 5 unique features and recommended for farms feeding 50-1500 bales annually, the self-loading 3-point linkage mounted Unrolla bale feeder excels in handling even the tightest round baled silage, as well as dry hay, loose silage, maize, fodder beet, and more.

5 reasons to invest in a Hustler Unrolla mounted bale unroller

1. Flexible and compact design

Do you operate in barns, outdoors, on steep country, with a tractor, a front-loader, a telehandler or even a skid steer? Do you feed out round bales of hay or silage, supplement with loose feed, grains, cattle cakes or fodder beet? With the flexible configuration of the Unrolla round bale feeder range, your machine will suit all the above. The mounted Unrolla can also be connected from either end, which makes it manoeuvrable in tight spaces. No other mounted unroller allows this level of versatility in such compact and lightweight machine, which gives you peace of mind, should you want to change the way you operate.

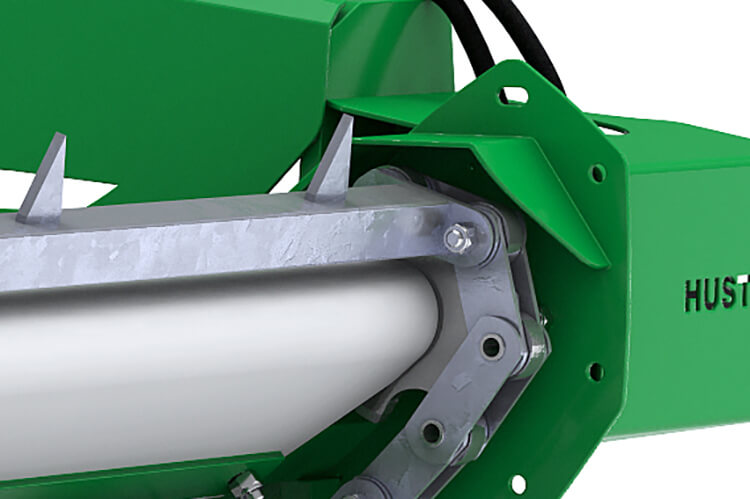

2. Hands-free self-loading

The integrated tines and the unique patented Hustler’s Snaplox™ auto connect/disconnect hands-free loading system saves you time, saves you having to tug on a rope to disconnect, and saves you from twisting your back. It’s fail-safe, fast and operates naturally. It’s also the perfect feature when you choose to fit your unroller at the front of your tractor or telehandler.

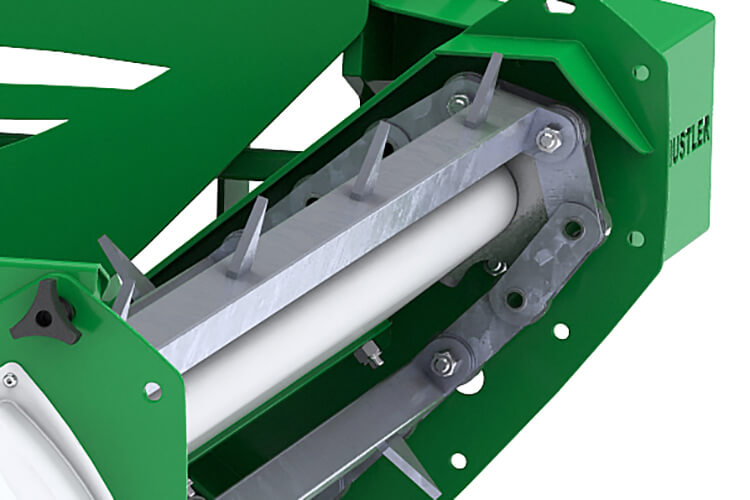

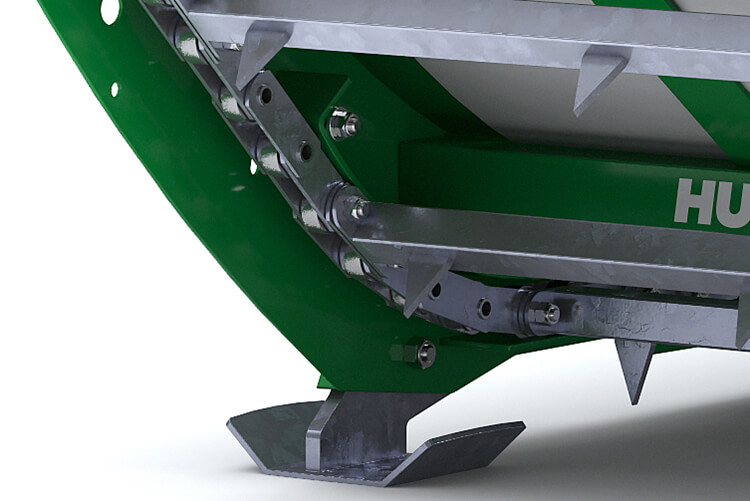

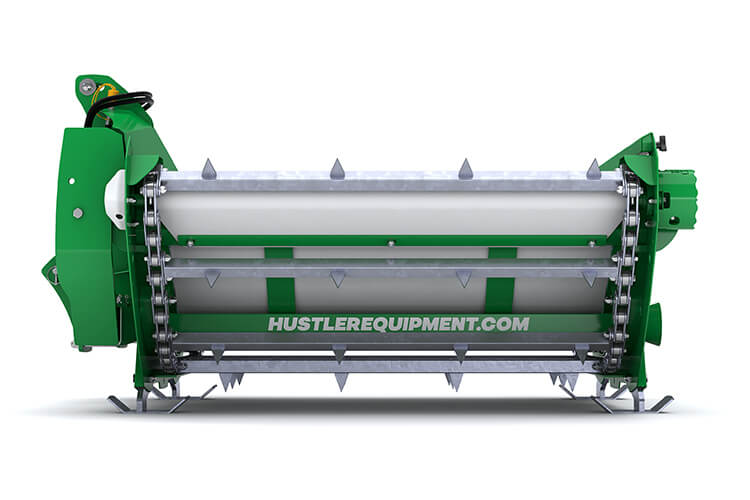

3. Toughest slat system

The toughest chains and floor bars on the market are bullet-proof and lasts the entire lifespan of the Unrolla. Super strong roller chains with a combined strength of 24,000lbs and rugged 40mm x 40mm (1.5 in x 1.5 in) galvanized bars which are the strongest on the market with thicker wall section and stronger teeth. The 15 floor bars are bolted to the chain which results in a resilient, solid and easily replaceable system.

4. Fully enclosed cradle

The Unrolla feeding cradle is made from a tough thermoform fully enclosed polyethylene floor with covered drive shafts which eliminate wrapping. It’s non-corrosive, impervious to UV, slippery, and extremely shock resistant. And it’s fully enclosed, meaning no more wastage of expensive high-quality feed and added versatility as you can feed out loose materials. The mounted Unrolla takes 4’ long bales (Unrolla LX104) and a longer bed can take up to 5’ long bales (Unrolla LX105*).

*This model is available in North America only

5. Low and easy maintenance.

Just greasing 4 nipples is all it takes to maintain the Unrolla round bale feeder. That’s because instead of bushes we use long-lasting, fully sealed self-aligning block bearings, mounted outboard to keep them clean and free of damage from acidic silage juices. We’ve also added bearing covers that prevent debris from causing damage.

Product Customiser

Select the product, then options and accessories to create your enquiry.