- Home

- Bale Feeders

- Trailed Bale Unrollers

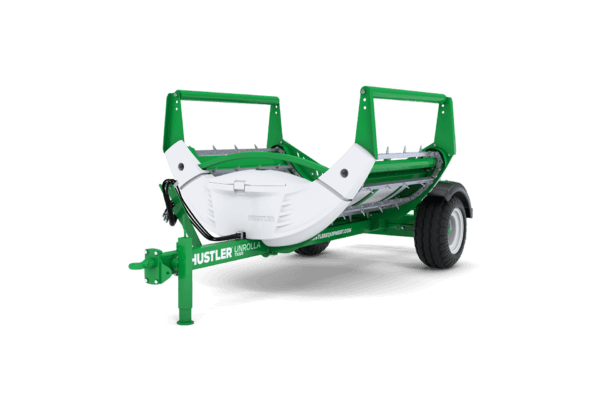

Trailed Bale Unrollers

The tough yet simple design of the Unrolla TX205 is self-loading trailed bale feeder that carries two bales per load and feeds out the widest variety of round bales, balage, silage, hay or straw, and even maize bales! It’s loaded with unique and patented features that make the chore of feeding bales easier than ever before.

Trailed self-loading two bale feeder.

The latest series 2 model retains the fundamental Hustler advantages such as the unique chassis design that protects the chains from dragging on the ground, the patented Total Control self-loading system, the toughest chain/floor setup on the market, and the ultra-low maintenance roller bearings and adds several improvements such as covered drive shafts to prevent wrapping, larger wheels for improved ride, improved stability, large string box as standard, and a beefier rear loading system for longer life.

Key Benefits

Easy to use

The double bale feeder has single level feed control, making it very easy to use and ideal for share milkers.

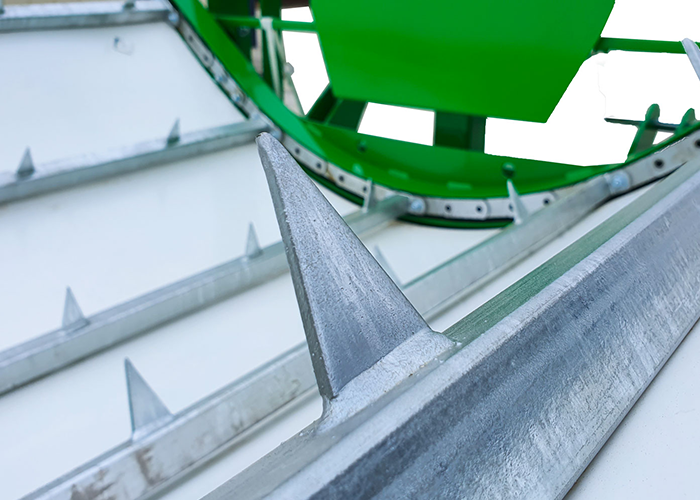

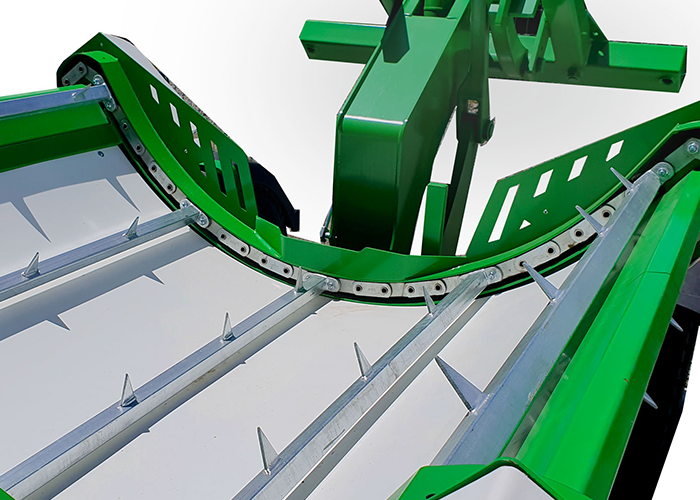

Toughest chains on the market

Super strong roller chains with the combined strength of 24,000 lbs, with tough 40mm x 40mm (1.5 x 1.5 in) zinc-plated bars. Bars are bolted to the chain, a stronger and more easily replaceable system.

Tough polyethylene floor

Non-corrosive, impervious to UV, slippery, easily repairable and very shock resistant. Fully enclosed – no wastage of expensive feed. The long bed can take 5’ long bales

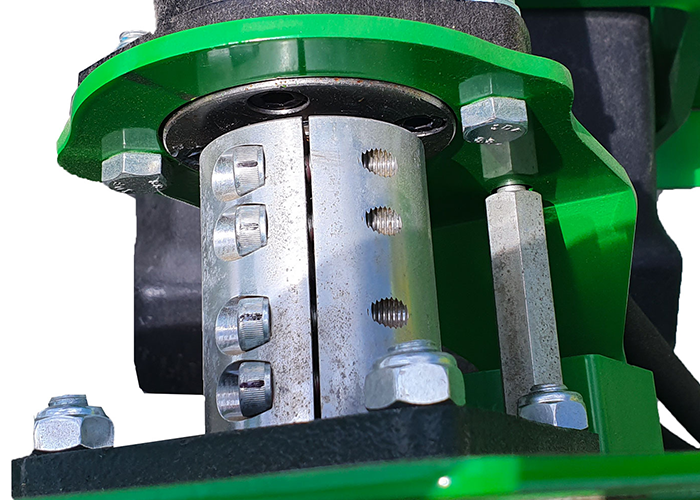

Low maintenance

Instead of bushes we use longer lasting block bearings, mounted outboard, to keep them clean and free of damage.

Chassis design

Our fully enclosed chassis prevents rust by stopping water from getting in. We’ve built the Unroller Trailed Round Bale Feeder with plenty of ground clearance to minimise bellying out and to avoid damage to chains and feed bars when it does touch the ground, we’ve made the underside of the chassis smooth, so it slides until the wheels gain traction again. Impressive strength to weight ratio has been achieved by constructing the Unroller Trailed Round Bale Feeder from high tensile steel, which is 50% stronger than mild steel. Bolted construction eliminates stress cracking common with some conventional Bale Feeders.

Hustler’s Unique Total Control Loading

The (TCL2) system that has revolutionized bale handling since it was introduced eight years ago. With just one hydraulic cylinder to complete the entire loading operation and a new gas strut to help reset the loader, the TCL2 is the fastest loading system out there. With only one ram it’s safer and less demanding on your tractor’s hydraulics. Unlike other systems, the operator can reverse the bale if necessary, even once the bale is positioned low over the cradle for unwrapping.

See it in Action

Product Customiser

Select the product, then options and accessories to create your enquiry.

Unrolla TX205 trailed round bale feeder

Includes as standard equipment:

- Drive shaft covers

- String box

- Bearing covers

- Larger 11.5/80-R15.3 Wheel Assemblies

Options and Accessories

Mudguards / Fenders

Keep feed clean from contaminants when feeding in muddy conditions.

Quick-Hitch Skid/Foot

Add a quick hitch foot to the drawbar to make it easier for connected when using a quick hitch.

Extra Loading Tyne

Adding extra loading tynes to your trailed bale feeder is ideal for handling larger square bales that require additional support. As the tynes are a bolt-on option, you can retrofit them on any trailed models you use.

Side Rollers (Mounted)

Prevents your bale from falling out of the cradle when operating in hilly country, and allows you to occasionally feed out square bales.

Enquire now

Your selection

Selected product

Selected Options and Accessories

What you'll get

- Access to a dedicated Hustler expert

- No Obligation Quote

- Your Quote Within 24 Hours