Hustler Global

- Home

- Feedout Wagons

- Combi CM Multi-Feeder Range

Combi CM Multi-Feeder Range

All Round & Square Bales, Silage, Root Crops & Food Waste

How do you make the best better?

Hustler’s latest Combi CM livestock feeders come loaded with features – 43 years proof in the field is one of them. Combi’s Feed anything ability paired with Hustler’s mindset of continual improvement with regular constructive feedback from farmers around the world and you’ve got the best of the best.

Don’t just take our word for it, see the CM in action on your farm by calling a Hustler livestock feeding expert on the number at the top of this page.

Key Benefits

Versatility

Toughest Chains / Bars

Load Dividing

Visibility

Accurate Delivery

Safe Loading

Joystick Control

Drawbar Clearance

Unbeatable Versatility - One Machine Any Feed

If you’re feeding a variety of bales, silage or any other supplementary feed, then a Combi CM is the only feeder you’ll need. The Combi Feeder range is able to feed all types, shapes and sizes bales including straw, hay and baled silage, fine chop silage, maize silage, root crops and literally any type of feed you can lay your hands on. The unique elevator design delivers feed out of the side of the machine allowing you to feed into troughs, feed-pads, bunks or open pasture without spillage

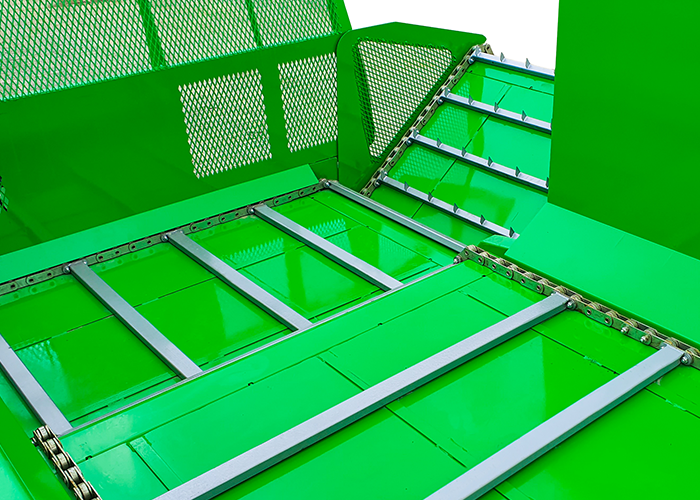

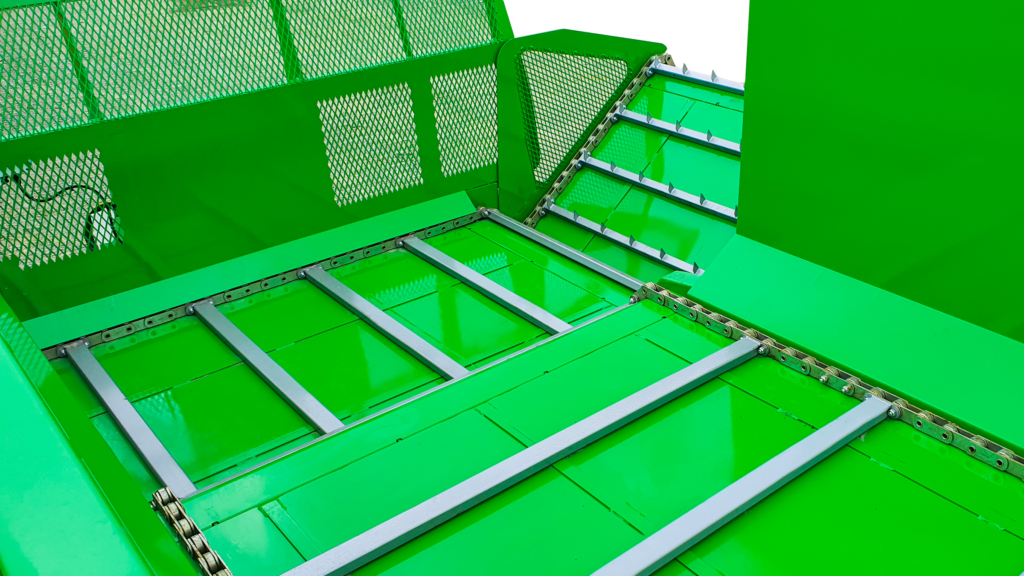

Toughest Chain & Bar setup on the market

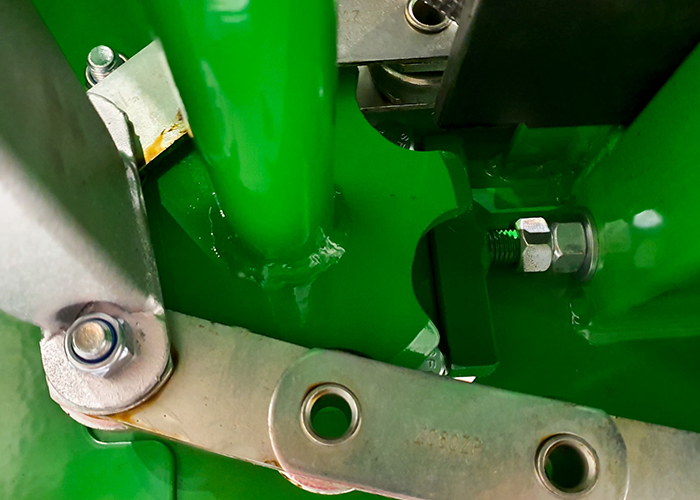

Using a basic principal from the tractor pull sled vs wheels, with Combi CM instead of dragging the load forward like a sled we used 12,000lb roller chains on all floors to substantially lowering the drag on the drives, chains and bars, kissing good-bye to chain problems!

And by using a single bar set up on each floor by build bars stronger than twin floor bars eliminated the need for extra sprockets, bearings, wearing parts and on-going maintenance

Load Dividing System

Proven over 43 years the unique and simple dividing system of Combi reduces loads and stresses on drives, motors, shafts and the floor extending the working life of the feeder.

Unbeatable Visibility

With the industry-leading visibility and the ability to see the entire load from the comfort of your seat feeding out the perfect feed-rows has never been easier and puts you in control! Even with the new elevator spill panels, now you can see exactly how much feed is coming up the elevator for improved feed control.

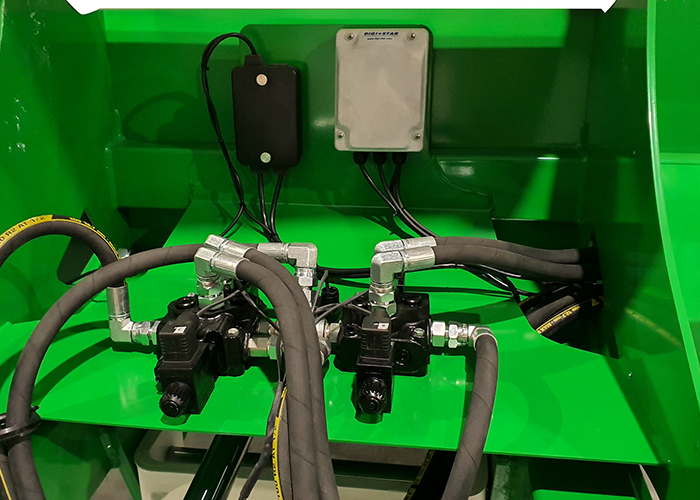

Accurate Feed Delivery

The Combi CM Feeders are scale ready as standard, which allows you to add the weighing option when it suits your operation so you can accurately measure the correct amount your herd needs, reducing waste and increasing the performance of your farm. And the tilting elevator makes for accurate bunk or trough feeding minimizing spillage.

Quick, Safe & Easy Loading

The low loading height of the Combi CM Range and great visibility make loading of any feed material or fodder with tractor loader quick and easy. And thanks to farmer feedback the sides are now higher to prevent second stacked bales from spilling during transport

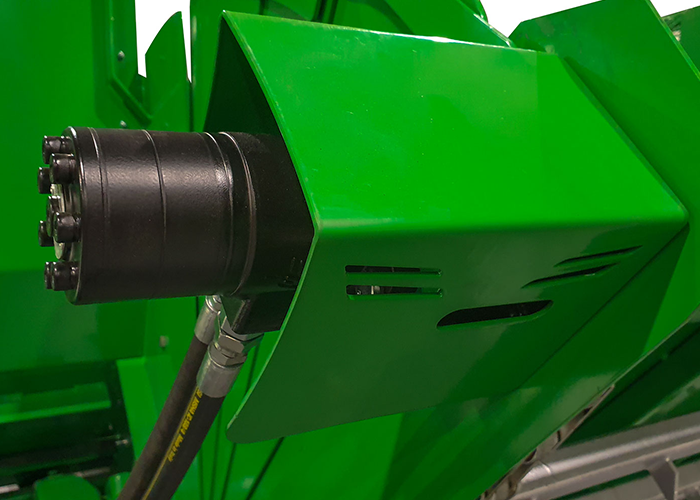

Tried & True Control System

The Combi CM Range comes standard with the original Combi control system which has taken more than 4 decades to perfect providing the operator with full control over each floor for more versatility when feeding bales or chopped feeds.

Other control choices are available as optional extras.

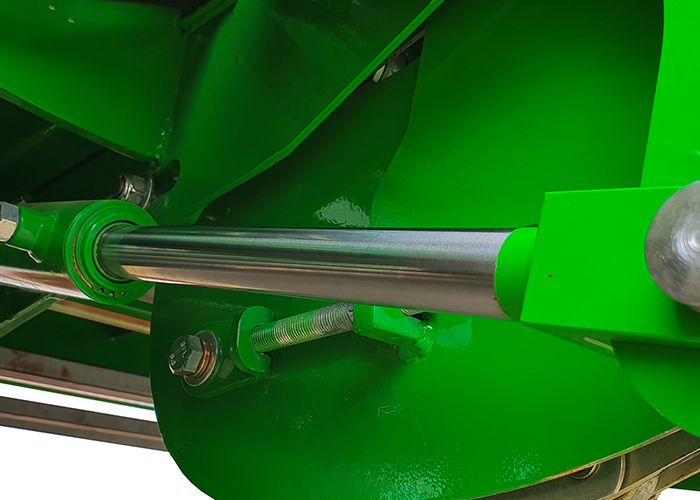

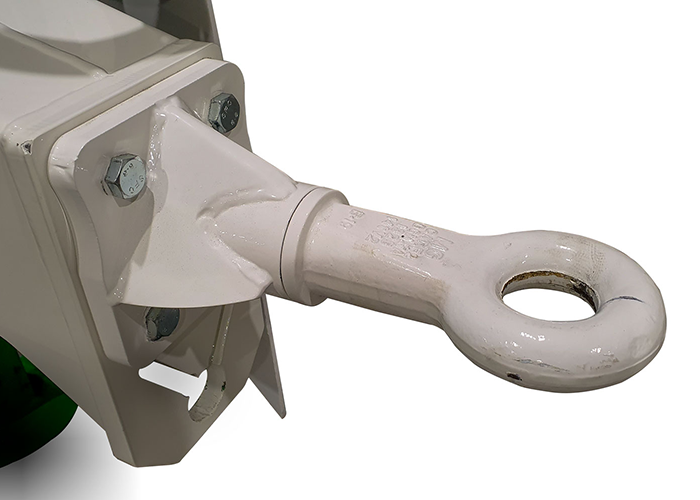

Massive Drawbar Clearance

The unique and improved drawbar design offers industry-leading clearance and a major advantage in maneuverability making life easier for operators in tight lanes and gateways. This reduces the possibility of damaged gate posts or the machine due to operator error.

Product Customiser

Select the product, then options and accessories to create your enquiry.

COMBI CM116

Includes as standard equipment:

- Access Ladder

- Feedpad Kit

- Elevator spill retainer panels

- Scale Ready

- Central axle greasing

Options and Accessories

Feedlink In-Cab Mounting and Display

Feedlink In-Cab Mounting and Display

FeedLink in-cab mounting and display for wireless scales includes iPad & Ram mounting system

Road Visibility Kit - CM

Road Visibility Kit - CM

Road Visibility Kit – Includes front & rear hazard panels, safety chains & LED road lights

Basic Load Sense Controls

Basic Load Sense Controls

The entry-level Combi control option (recommended for feeding chopped silage only). Requires 3 sets of hydraulics

Feed Control

Feed Control

Feed Control unique to Hustler has two operation modes for silage and bales providing the operator with semi-automated control when feeding silage or full control over each floor for more versatility when feeding bales giving you truly the best of both silage wagon and combination feeder in one machine.

Heavy Duty Oscillating Tandem Axle

Heavy Duty Oscillating Tandem Axle

Largest pivot surface and maximum oscillation.

Enquire now

Your selection

Selected product

Selected Options and Accessories

What you'll get

- Access to a dedicated Hustler expert

- No Obligation Quote

- Your Quote Within 24 Hours