THE LEGEND REBUILT

Introducing the all-new Combi RX² multi-feeder range. With unique features delivering unprecedented feeding versatility, standing as the lowest maintenance wagon on the market, offering unrivaled maneuverability and enhanced feed control. Built upon the success of its predecessor, the Combi RX² incorporates valuable user feedback for an even better feeding out experience.

With more than a decade of extensive product development and testing, working on large-scale farms and ranches around the world, the Combi RX² range is ready for whatever you throw its way.

What sets the Hustler Combi RX² range apart?

1. Unbeatable Versatility - One Machine, Any Feed

If you’re feeding a combination of bales, silage, root crops, or any other supplementary feed, then the Combi RX² is the only feeder you’ll need.

The Hustler Combi multi-feeder range is designed to accommodate all types, shapes, and sizes of bales, including straw, hay, baled silage, fine chop silage, maize silage, root crops, and virtually any type of feed you have. Its unique elevator design enables feed delivery from the side of the machine, allowing you to easily feed into troughs, feed pads, bunks, or open pastures without any spillage.

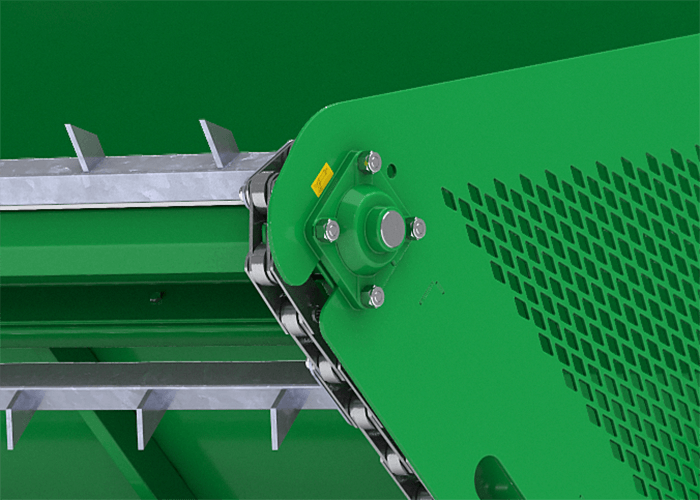

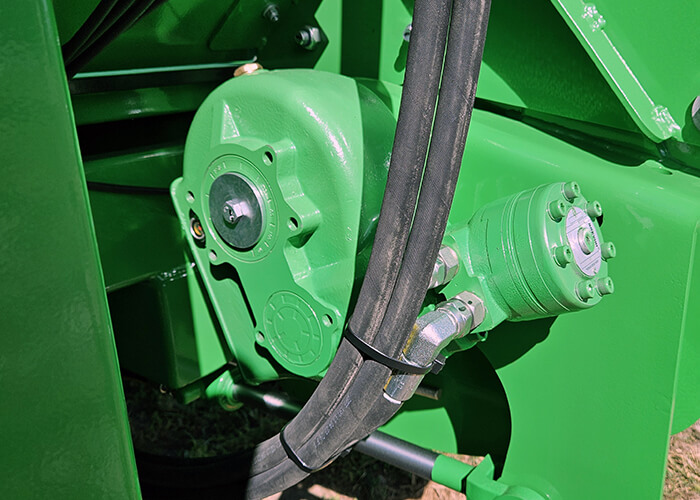

2. Chainless Reliability & Simplicity

With its chainless rear floor, greaseless components, and simplified design, the Combi RX² multi-feeder wagon takes the crown as the most reliable option on the market!

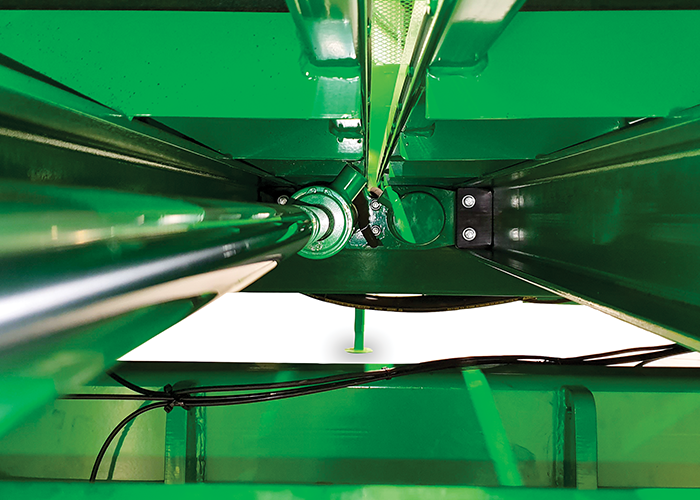

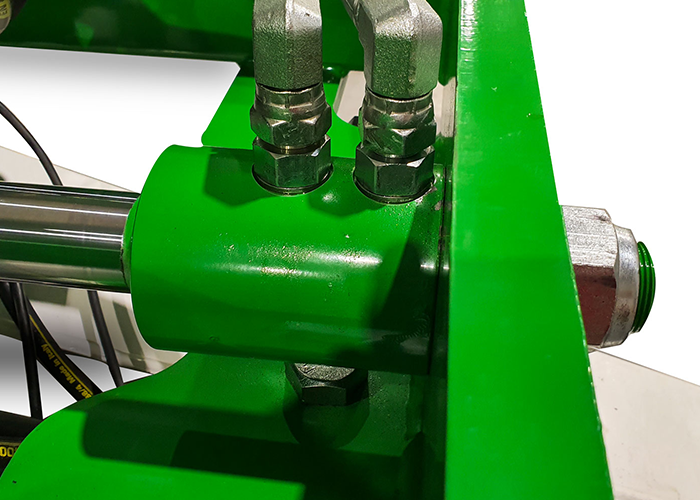

Featuring 100% hydraulic drive (no PTO), self-aligning bearings for durability, a single elevator ram, protected motor drives hydraulic and electric components, the Combi RX² range is engineered to significantly reduce operating and maintenance costs. Plus, with the added convenience of central greasing as a standard feature, you’ll spend more time in the field and less time in the workshop.

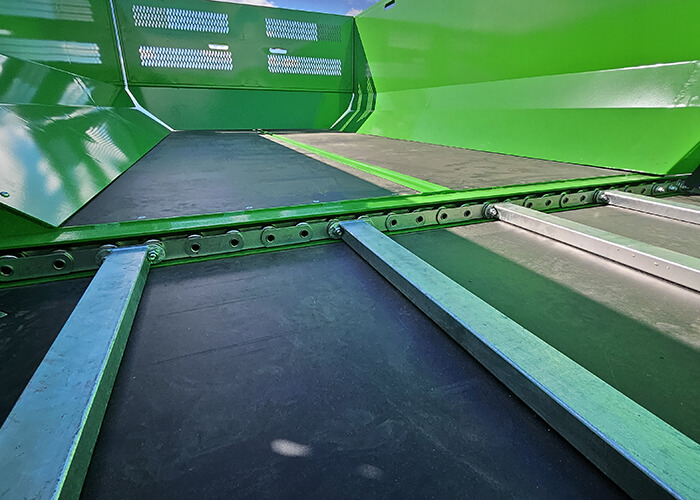

3. Trouble-free Stepless Floor and Load Dividing Design

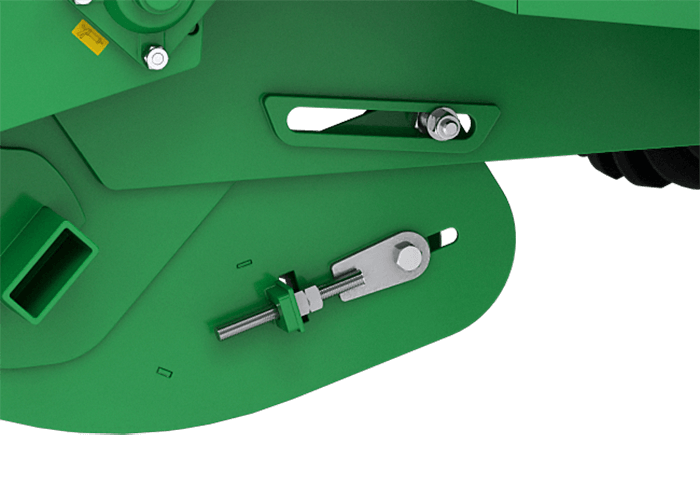

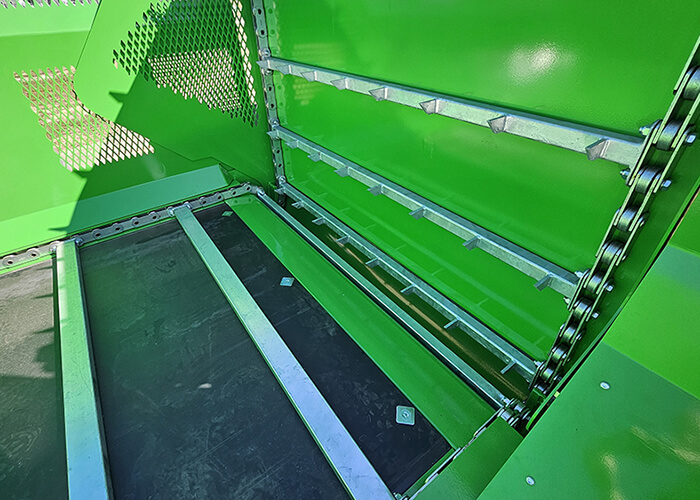

The Hustler Combi range features a flat floor design that ensures a smooth transition between the unique, 2-speed chainless rear bed floor and cross floor, eliminating any spillage of maize/corn silage between them.

This innovative design prevents downtime caused by root crops bending bars and jamming the rear bed floor. With no staged floors, you’ll enjoy ample ground clearance, making operation in rough terrain a breeze. Take a closer look at the internal bin design, exclusive to the Hustler Combi RX² range, and appreciate its simplicity. The proven dividing system effectively reduces loads and stresses on drives, motors, shafts, and the floor, significantly extending the wagon’s working life.

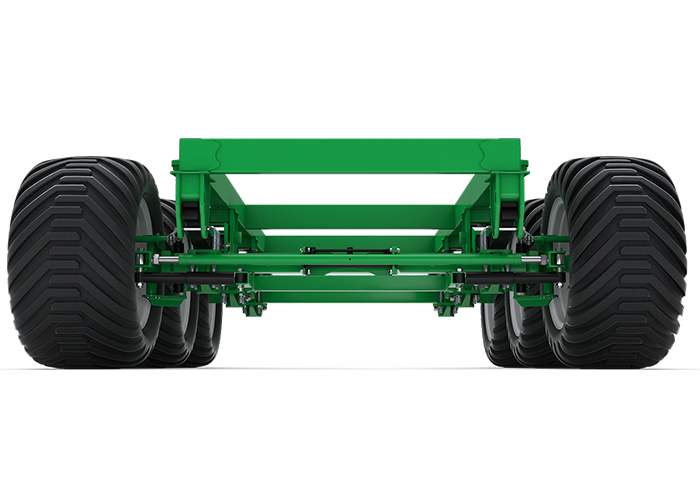

4. Compact Design for Unparalleled Manoeuvrability

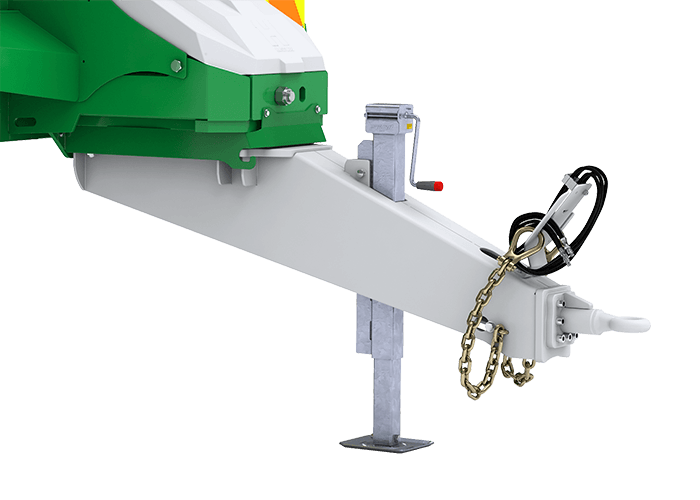

The Combi RX² feedout wagon range offers an average 28% increase in load capacity with bales compared to other multi-purpose wagons, making it the most compact and maneuverable option in its class.

With its unique and improved drawbar design, the RX² Range provides industry-leading clearance and enhanced maneuverability. This design minimizes the risk of damage to gate posts or the machine itself, offering operators a hassle-free experience. In fact, the RX148² boasts a remarkable turning circle of 7.8 meters (23 feet), while equivalent-sized wagons require 20.8 meters (65.6 feet)!

5. Unmatched Visibility

With industry-leading visibility on the load behind, feeding out perfect feed rows has never been easier, putting you in control.

The Hustler Combi RX² range offers see-through visibility on the bin and the elevator thanks to openwork panels. The ability to see the entire load from the comfort of your seat and the addition of new elevator spill panels allows you to see precisely how much feed you carry and how much is coming up the elevator, resulting in improved feed control and operator safety.

Product Customiser

Select the product, then options, and accessories to create your inquiry.