Hustler Global

- Home

- Feedlot Bale Unrollers

Feedlot Bale Unrollers

Self-loading 3-point-linkage mounted trough feeder

Feedlot Bale Feeder

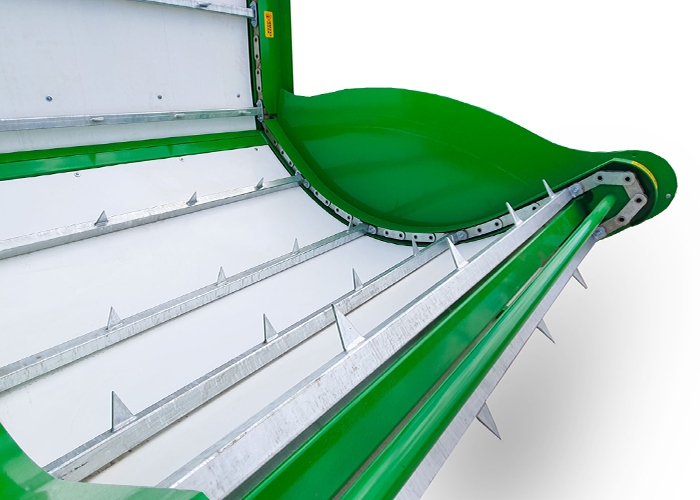

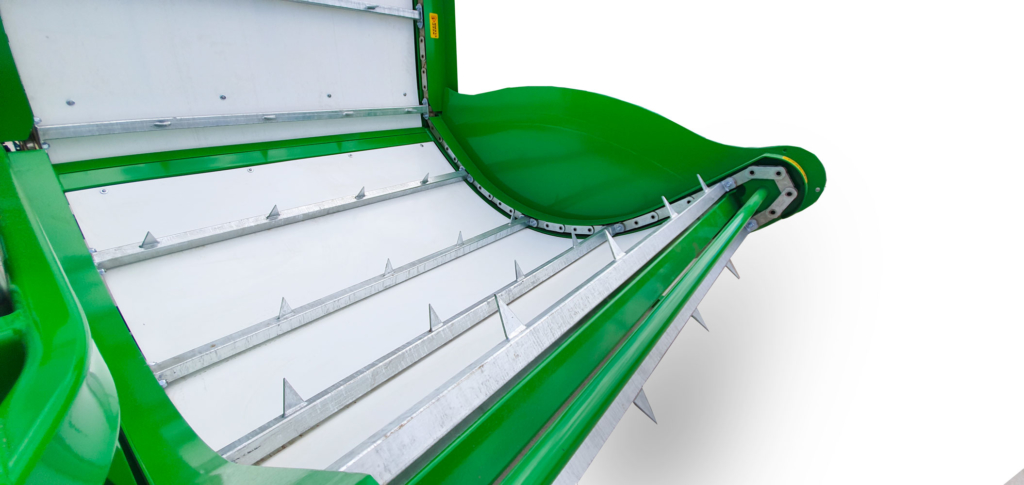

A self-loading 3-point-linkage mounted trough feeder suitable for feeding out into troughs, feed bunkers, over fences or onto feed pads a wide variety of mainly round bales and silage along with some square bales when using the optional sidebars. The LM105T feedlot bale unroller is suited for farms feeding out 50-800 bales each year.

Key Benefits

Easy to use

The LM105T feedlot bale unroller has single level feed control, making it very easy to use and ideal for share milkers.

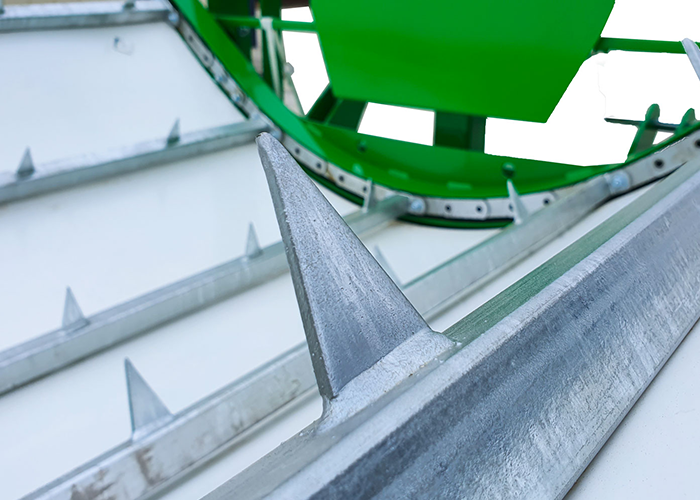

Toughest chains on the market

Super strong roller chains with the combined strength of 24,000 lbs, with tough 40 mm x 40 mm (1.5 in x 1.5 in) zinc-plated bars. Bars are bolted to the chain, a stronger and more easily replaceable system.

Tough polyethylene floor

Non-corrosive, impervious to UV, slippery, easily repairable and very shock resistant. Fully enclosed – no wastage of expensive feed. Long bed can take 5’ long bales.

Low maintenance

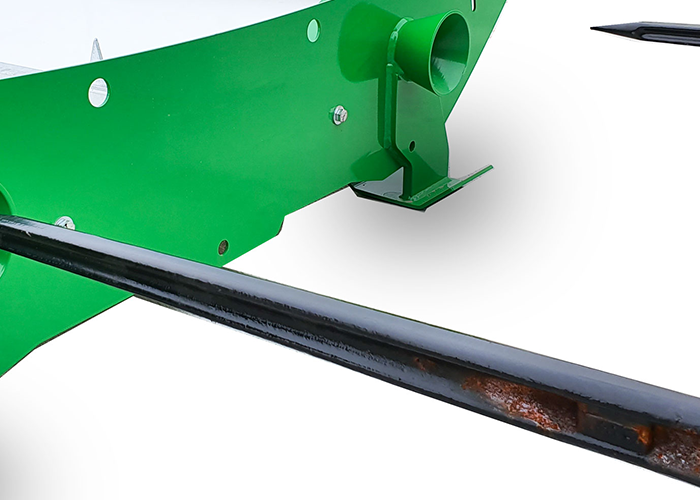

Instead of bushes we use longer-lasting block bearings, mounted outboard to keep them clean and free of damage.

Best bale security on the market

The high rear bar means the bale cannot screw off the back on hills. Optional side rails are available.

Product Customiser

Select the product, then options and accessories to create your enquiry.

Unrolla LM105T

Options and Accessories

Ez Remote Control

Ez Remote Control

Making rebaling easy, the remote control valve can be positioned within a 160-degree arc to suit individual operator preference and provides improved visibility of the feed flow into the baler. The control levers are mounted on an arm to keep the operator outside the dust zone.

Enquire now

Your selection

Selected product

Selected Options and Accessories

What you'll get

- Access to a dedicated Hustler expert

- No Obligation Quote

- Your Quote Within 24 Hours