Hustler Global

- Home

- Feedout Wagons

- EzFeed Silage Wagon Range

EzFeed Silage Wagon Range

Sick of frequent tightening and derailed link chains? With a slew of innovative new features, EzFeed resolves the most painful frustrations that have plagued conventional silage wagons for over 30 years!

Strength, reliability and simplicity combine to provide the industry’s best uptime and make these the best silage wagons money can buy. That’s why the high end users are making the switch to EzFeed for maximum uptime!

EZFEED SILAGE WAGONS SM130 | SM150 | SX180 | SX210

EzFeed SM130 | EzFeed SX210 (*models may be shown with optional extras)

Feeding silage made Ez

The most simple, reliable silage wagon on the market designed for farmers who simply cannot afford downtime and rely solely on silage as the supplementary feed of choice. Ideal for trough feeding, feeding under a wire, feeding along a fence line avoid trampling and general pasture feeding.

5 Reasons why EZFEED is the best-in-class

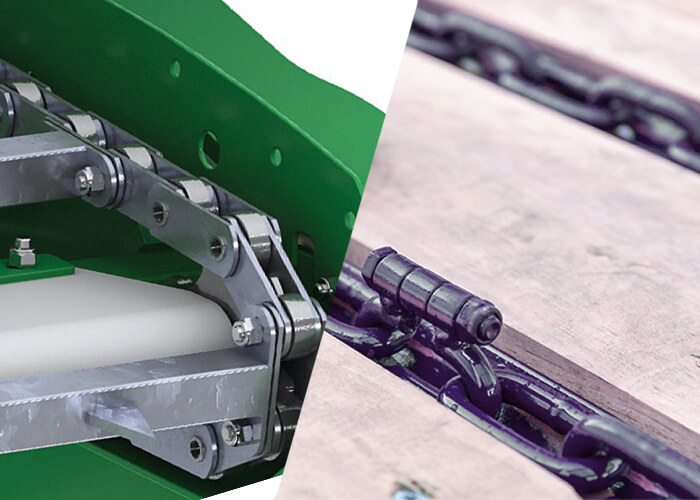

1. 100% Roller Chains | Industry First

The biggest frustration and #1 issue for reliability with conventional silage wagons is derailing chains and the constant adjustments to keep them tensioned which if overlooked, leads to them snapping! This is due to the high wear characteristics of point loading in each link with link chains. We resolved this issue with Roller Chains

With EzFeed gone are the days of trouble-some link chains and conveyor belts that require constant adjustment, fine-tuning and are often slipping or breaking disrupting your feeding program.

EzFeed is the only forage wagon on the market to run a 100% roller-chain design. Once run in, you rarely need further adjustments, eliminating this constant hassle and downtime.

2. Virtually Indestructible Hungry Boards | Industry First

High-impact resistant and rotational moulded, our replaceable Hungry Boards can take a beating from your front-loader without turning to splinters and making your nice EzFeed silage wagon look all dinged up. Another industry first from Hustler.

3. TwinFeed | Industry First

The first silage wagon to feature left or right hand feed discharge for more feeding versatility. And discharge floor with side-shift allows for easy setup when feeding into troughs.

The optional patented Auto Change system detects the direction of the side shift and automatically changes the side of feed distribution without the operator having to think! It’s all hydraulic trickery so is ultra-reliable without any electrics to keep things Easy, Simple and fool-proof

4. Low-skill operators dream | Simple Operation

As the name suggests EzFeed makes feeding silage easier the easiest it’s ever been! As standard only one set of hydraulics is all it takes to connect and power the whole machine and our clever adjustable load-sensing hydraulics takes care of the rest making EzFeed the ideal wagon for low-skilled staff.

- Simply set how far out from the machine you want to place the windrow

- Choose the size of windrow you like

- That’s it, set and forget and EzFeed does the rest. With EzFeed it’s truly that simple.

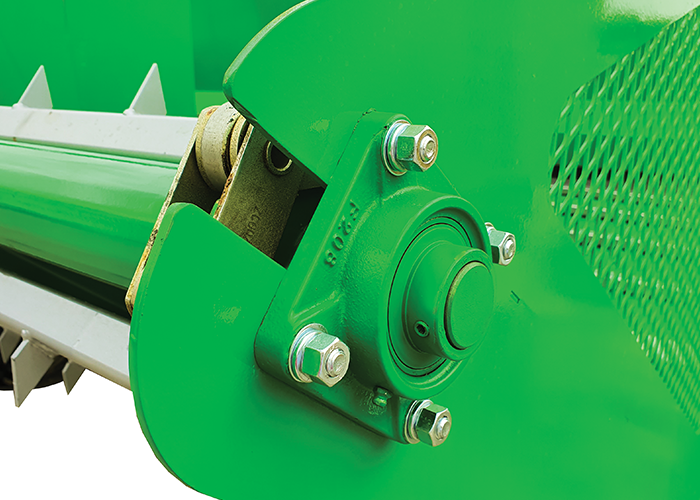

5. Unique Uni-Body Design | Proven Platform

Built utilising our proven Combi wagon platform EzFeed has the toughest axle design on the market by a country mile, large suspension travel, comes scale ready for our industry first FeedLink feed management system which weighs on both the jack/skid and drawbar, impact resistant puck-board floors, toughest bars and more.

Product Customiser

Select the product, then options and accessories to create your enquiry.

EZFEED Silage Wagon SM130

Includes as standard equipment:

(model in picture shown with optional 500/50 x 22.5 wheels)

100% roller chains

TwinFeed™ featuring left and right-hand feed discharge

Crash bumper bars

Remote greasing

Access ladder

Rotomolded hungry boards

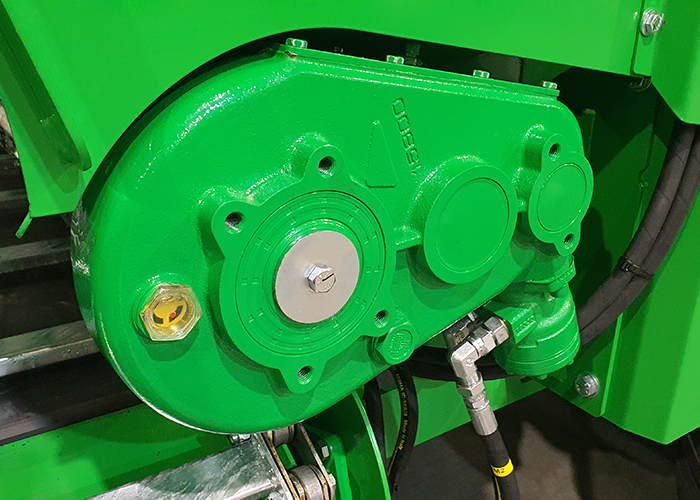

Sealed reduction drive gearbox

Heavy-duty oscillating tandem axle with large pivot surface and maximum oscillation

400/60 x 15.5 flotation grip tread wheels

EZFEED Silage Wagon SM150

Includes as standard equipment:

100% roller chains

TwinFeed™ featuring left and right-hand feed discharge

Crash bumper bars

Remote greasing

Access ladder

Rotomolded hungry boards

Sealed reduction drive gearbox

Heavy-duty oscillating tandem axle with large pivot surface and maximum oscillation

500/50 x 22.5 Flotation Grip Tread Wheels

EZFEED Silage Wagon SX180

Includes as standard equipment:

100% roller chains

TwinFeed™ featuring left and right-hand feed discharge

Crash bumper bars

Remote greasing

Folding Premium Ladder

Rotomolded hungry boards

Sealed reduction drive gearbox

Heavy-duty oscillating tandem axle with large pivot surface and maximum oscillation

500/50 x 22.5 Flotation Grip Tread Wheels

EZFEED Silage Wagon SX210

Includes as standard equipment:

100% roller chains

TwinFeed™ featuring left and right-hand feed discharge

Crash bumper bars

Remote greasing

Folding Premium Ladder

Rotomolded hungry boards

Sealed reduction drive gearbox

Heavy-duty oscillating tandem axle with large pivot surface and maximum oscillation

500/50 x 22.5 Flotation Grip Tread Wheels

6 Wheel Brakes

Options and Accessories

Road Visibility Kit - EZFEED

Road Visibility Kit - EZFEED

Road Visibility Kit – Includes front & rear hazard panels, safety chains & LED road lights

Feedlink In-Cab Mounting and Display

Feedlink In-Cab Mounting and Display

FeedLink in-cab mounting and display for wireless scales includes iPad & Ram mounting system

Euro Hitch Adapter - EzFeed

Euro Hitch Adapter - EzFeed

Easily replace the standard headstock hitch of your EzFeed silage wagon with a bolted Euro Hitch Adapter (includes drawbar extension).

Quick Hitch Skid/Foot - EzFeed

Quick Hitch Skid/Foot - EzFeed

Add a quick hitch foot to the drawbar to make it easier for connected when using a Hustler SwiftHitch quick hitch.

Feedlink In-Cab Mounting and Display

Feedlink In-Cab Mounting and Display

FeedLink in-cab mounting and display for wireless scales includes iPad & Ram mounting system

Road Visibility Kit - EZFEED

Road Visibility Kit - EZFEED

Road Visibility Kit – Includes front & rear hazard panels, safety chains & LED road lights

Euro Hitch Adapter - EzFeed

Euro Hitch Adapter - EzFeed

Easily replace the standard headstock hitch of your EzFeed silage wagon with a bolted Euro Hitch Adapter (includes drawbar extension).

Quick Hitch Skid/Foot - EzFeed

Quick Hitch Skid/Foot - EzFeed

Add a quick hitch foot to the drawbar to make it easier for connected when using a Hustler SwiftHitch quick hitch.

Feedlink In-Cab Mounting and Display

Feedlink In-Cab Mounting and Display

FeedLink in-cab mounting and display for wireless scales includes iPad & Ram mounting system

Feedlink Scale system with New PowerMax scales

Feedlink Scale system with New PowerMax scales

Scale system (6 cells) PowerMax provides accurate, precise weighing results.

Road Visibility Kit - EZFEED

Road Visibility Kit - EZFEED

Road Visibility Kit – Includes front & rear hazard panels, safety chains & LED road lights

Quick Hitch Skid/Foot - EzFeed

Quick Hitch Skid/Foot - EzFeed

Add a quick hitch foot to the drawbar to make it easier for connected when using a Hustler SwiftHitch quick hitch.

Euro Hitch Adapter - EzFeed

Euro Hitch Adapter - EzFeed

Easily replace the standard headstock hitch of your EzFeed silage wagon with a bolted Euro Hitch Adapter (includes drawbar extension).

Hydraulic Side Floor Sideshift

Hydraulic Side Floor Sideshift

If you frequently require changing feeding direction, the hydraulic side-shift option is your ideal solution. This innovative feature automatically adjusts the direction of the cross conveyor to feed out from the side where the conveyor is extended. With this convenient functionality, you can seamlessly switch between left and right feeding sides without the need to manually toggle a switch or leave the comfort of the cab.

Feedlink Scale system with New PowerMax scales

Feedlink Scale system with New PowerMax scales

Scale system (6 cells) PowerMax provides accurate, precise weighing results.

Feedlink In-Cab Mounting and Display

Feedlink In-Cab Mounting and Display

FeedLink in-cab mounting and display for wireless scales includes iPad & Ram mounting system

Quick Hitch Skid/Foot - EzFeed

Quick Hitch Skid/Foot - EzFeed

Add a quick hitch foot to the drawbar to make it easier for connected when using a Hustler SwiftHitch quick hitch.

Road Visibility Kit - EZFEED

Road Visibility Kit - EZFEED

Road Visibility Kit – Includes front & rear hazard panels, safety chains & LED road lights

Euro Hitch Adapter - EzFeed

Euro Hitch Adapter - EzFeed

Easily replace the standard headstock hitch of your EzFeed silage wagon with a bolted Euro Hitch Adapter (includes drawbar extension).

Enquire now

Your selection

Selected product

Selected Options and Accessories

What you'll get

- Access to a dedicated Hustler expert

- No Obligation Quote

- Your Quote Within 24 Hours