Feeds any type of bales. Minimises feed waste.

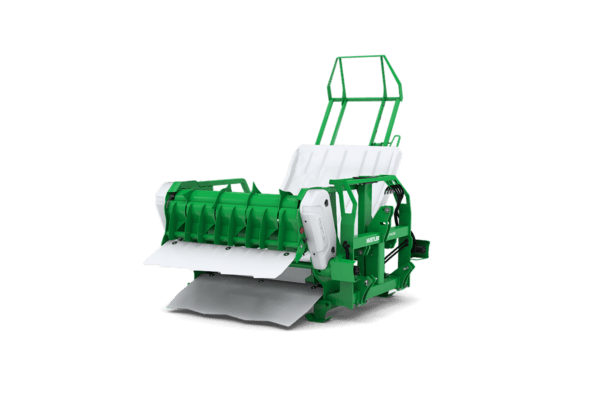

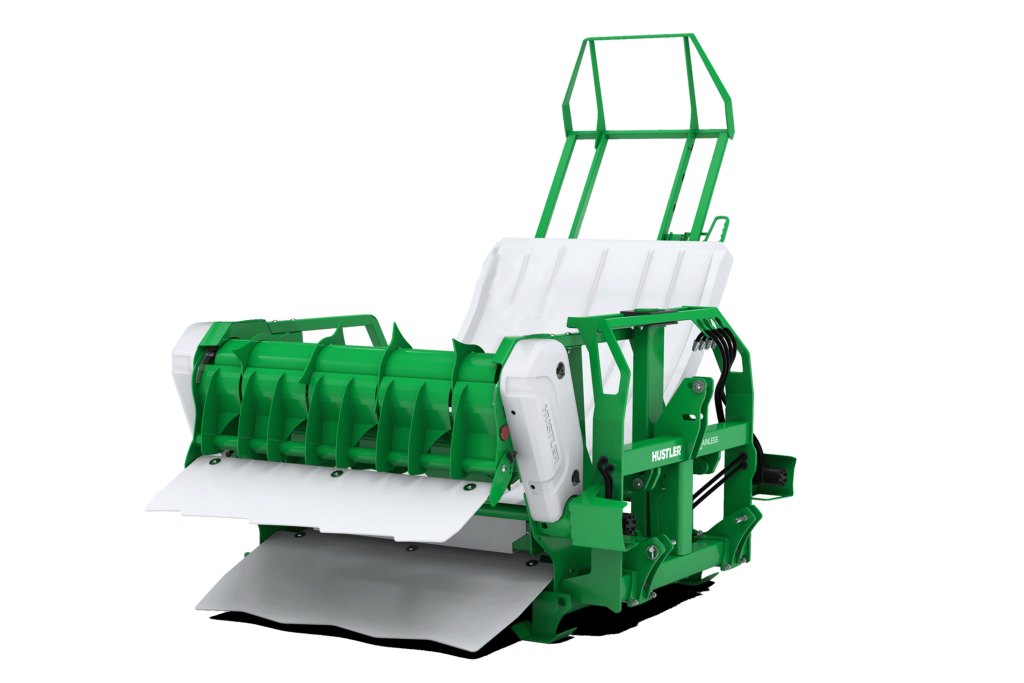

The all-new Chainless LX² series mounted bale feeder is the ultimate solution for efficient, waste-free feeding. Designed to handle any bale type – both round and square – with ease, the Chainless LX² series is low maintenance, features a hands-free quick hitch system, adjustable platform and heavy-duty construction for unmatched reliability. Experience quieter, cleaner operation and improved livestock wellbeing while saving on fuel and feed costs, all backed up with our legendary 5 year NO BULL warranty. Future-proof your feeding operation with the Hustler Chainless system, where versatility meets performance.

4 Reasons to choose a Hustler mounted Chainless bale feeder:

1. Quiet and reliable operation

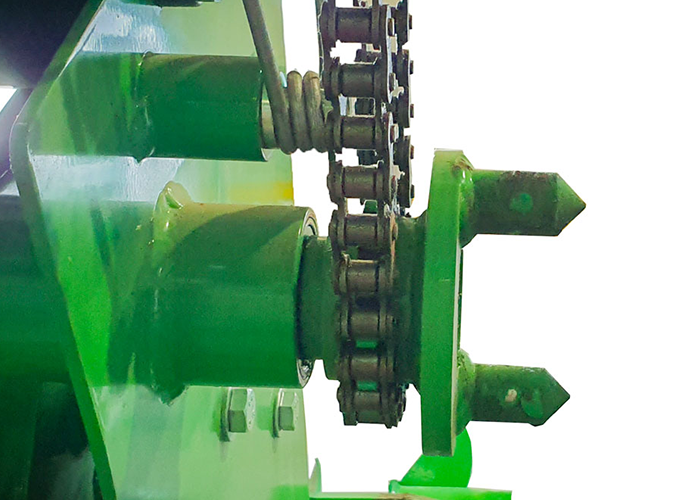

With the Chainless system, say goodbye to troublesome feed chains! This key advantage ensures a dependable, low-maintenance, and noise-free feeding process by keeping things simple.

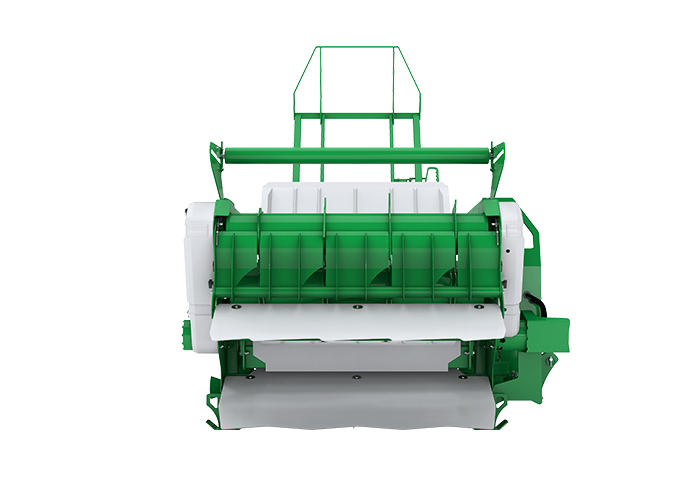

Instead of conventional feed chains or flails, this system employs a robust hydraulically driven polyethylene platform that gently feeds bales through two low-speed rotors. The rotors tease the hay, resulting in virtually silent and dust-free feeding, preventing air filter clogs, keeping grease points clean and prioritising the comfort of your livestock. With a complete drive and shaft system operating on bearings rather than bushings, it reduces wear and moving parts, offering minimal maintenance, less downtime, and an extended service life. This ultra-low power requirement can save up to 60% on fuel compared to PTO-powered machines and enables it to be used with even small tractors.

2. Versatility across all bale types

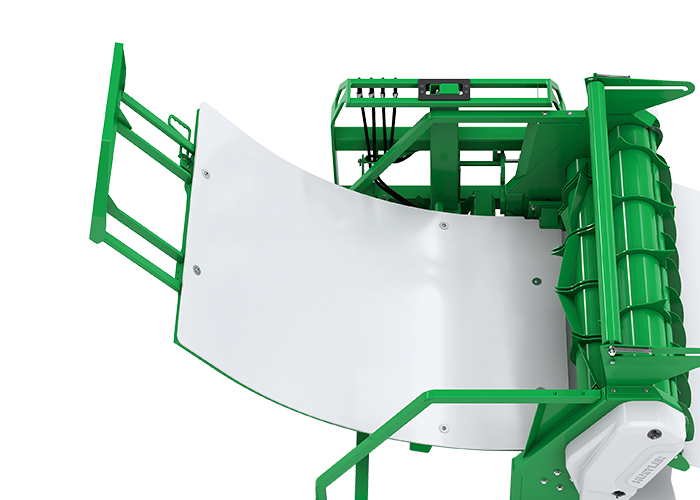

The Chainless system has been developed to future-proof your operation, being able to handle all bale types and shapes, round or square dry hay to wrapped bales.

The shape of the two 3:1 low-speed ratio rotors, coupled with an innovative wiper panel preventing materials building up, and the curved bale platform design improve penetration, making it efficient even with dense, sticky, rotor-cut or frozen bales whether they are round or square. The bottom axial rotor ensures an excellent grip on both tight and loose bales, simplifying the feeding process by keeping the bale centralised while feeding it out. The large bale chamber broadens the range of bales it can handle, minimising the need for constant platform adjustments, making it easy to use by all-skilled operators.

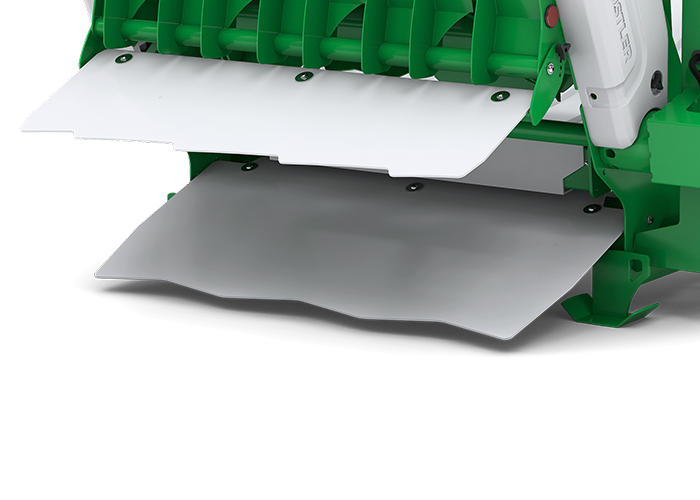

3. Minimise waste and maximise quality

Chainless also preserves the forage by gently teasing it apart with its unique 3:1 low-speed ratio rotors. This process avoids chopping or grinding the bale, leading to several benefits.

This system ensures total control over the size and length of the feed windrow, whether you’d like it thick for bigger animals or narrower for young heifers or sheep. The nutritional leaves are not separated from the stems, and the hay is not pulverised or lost as dust, making it more palatable for your livestock, easier to consume without competition, ensuring even access to the feed for the whole herd. Potential mould in a bale is separated without mixing, ensuring cattle consume fresh, clean hay. Our customers report remarkable reductions in mineral supplement consumption, up to 80%, and up to 20% less hay consumption for the same live weight gains, all with the same bales. As you get more control on where and how much you’re feeding, you can save up to 40% of your hay over the season!

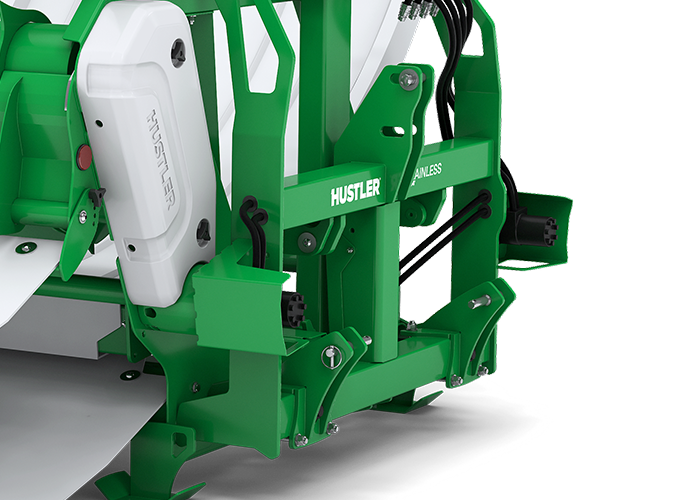

4. Snaplox™ auto connect/disconnect self-loading system

The Hustler’s patented Snaplox™ system automates connecting and disconnecting the headstock integrated bale tines to and from the bale feeder, guaranteeing an easy and hassle-free operation.

Instantly disconnect the headstock from the bale feeder, use the integrated tines to load the bale onto the feeder, and instantly reconnect the machine for feeding, without the need to get out of the cab or to tug on a rope to make the latching system work, reducing strain on your back. As the hydraulic system sits on the headstock, you don’t need to touch the hydraulic hoses during the loading/feeding process. Snaplox™ also allows you to mount your Chainless bale feeder at the rear on a three-point linkage or at the front on a front loader, telescopic loader, skid steer loader for added versatility.

Product Customiser

Select the product, then options and accessories to create your enquiry.