Hustler Global

This model is now replaced by the Combi CM106 feedout wagon.

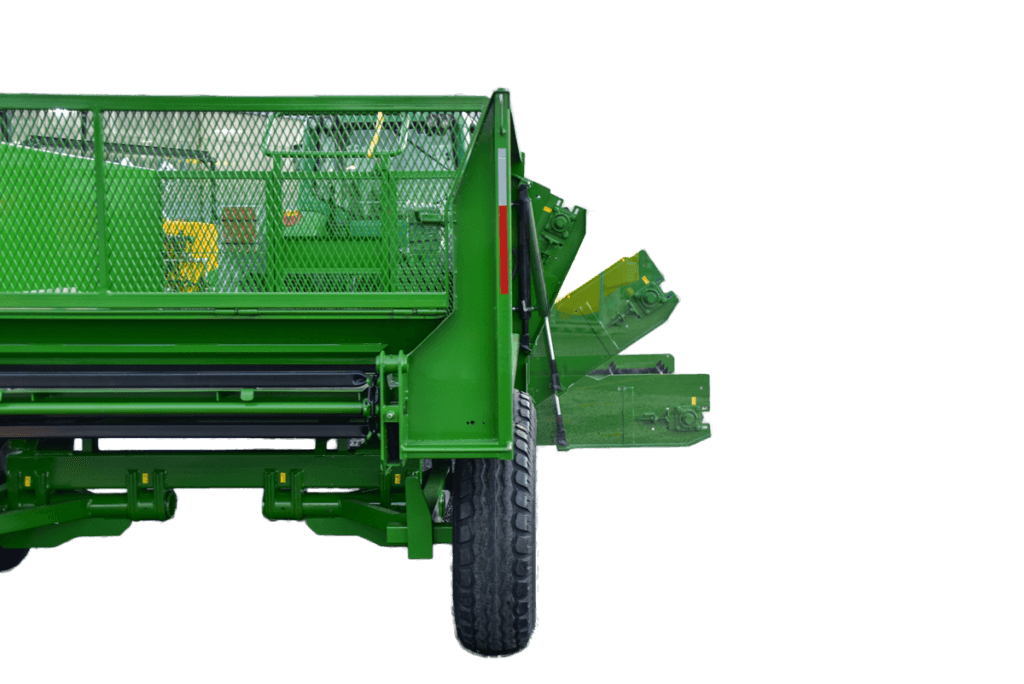

The Super Comby is the most versatile feed out machine on the market. It literally feeds out every supplementary type of feed you can lay your hands on, including all bale types, shapes and sizes with an in-built bale loading system. And any type of loose feed that can be loaded with a loader including fine chop silage, maize silage, root-crops, vegetables and more.

Comby feeders are the only milti feeder on the market that is scalable, meaning should you grow your operation, you’re not up for a new feeder. Simply add the forks and bin to any standard machine and the load level capacity increases from 339ft3 to 431ft3.

Benefits

- VERSATILITY – If you’re feeding a combination of bales, silage, root-crops or any other supplementary feed, then the Super Comby is the only multi-feeder you’ll need. Super Comby is able to feed all types, shapes and sizes bales including straw, hay and baled silage, fine chop silage, maize silage, root crops and literally any type of feed you can lay your hands on. The unique elevator design delivers feed out of the side of the machine allowing you to feed into troughs, feed-pads, bunks or open pasture.

- CONTROL – The unique design of the Super Comby provides the operator with more control and visibility of the task at hand. More control over the feed-row lets you maximise your feed by varying from light for sheep and deer to the heavier row for feeding cattle and anything in between with no big clumps left in the pasture. The ability to see the entire load from the comfort of your seat puts you in control of feeding.

- RELIABILITY – The combination of a tough, well-proven design with the design smarts of the unique load dividing system reduces loads and stresses on drives, motors, shafts and the floor extending the working life, reducing maintenance and less to wear out which lets you spend more time feeding out, and less time in the workshop.

- EASY TO USE – With a simple Joystick Control Feeding System only 2 double acting hydraulic outlets are required to operate the entire machine. Elevator, loading forks, main floor and cross floor giving you more control, from your fingertips. You have full control of the feed material, being able to forward and reverse all floor movements.

- SCALABILITY – With the Super Comby you have the ability to up-size your feeder as your farm grows, without the need to upgrade to a new wagon. Then add the rear bin at any time to the standard 339 cu ft Super Comby to increase capacity to 477 cu ft.

- COMPACT – The Super Comby is the most compact and manoeuvrable silage feeder and/or bale feeder in the 10 cbm class than to the ability to load the entire feeder, including the cross floor.

- ACCURATE FEED DELIVERY – All Comby feeders now come load cell ready as standard, which allows you to add the weighing option when it suits your operation so you can accurately measure the correct amount your herd needs, reducing waste and increasing the performance of your farm.

Specifications

CAPACITY

- Round bales (single layer): 3-6 (4-7 with optional forks)

- Medium squares (single layer): 4-6 (6-8 with optional forks)

- Large squares (8ft single layer): 3 (4 with optional forks)

- Loose silage (load-level): 339ft3 (431ft3 with optional bin extension)

- Loose silage (heaped load): 424ft3 (600ft3 with optional bin extension)

- Optional grain feeding system: 1102lb

- Optional Causmag spreader:165lb

SPECIFICATIONS

- Overall width: 108.3″

- Overall length: 235″ (330″ with optional forks)

- Overall height: 70.1″

- Overall height/loading height: 137.8″

- Tare weight: 90.55″ (110.6″ with forks and bin)

- Tare weight optional grain system only: 441 lb

- Standard tyres: 11.5 / 80 x 15.3

- Axle: Optional 2 or 4 wheel braking

- Weigh scales: Optional 4 cell

- Floor: Welded steel floor

- Joystick: In-cab electric finger tip control

- Hydraulics required: 2 pair double acting (Additional 1 pair double acting required for forks)

- Elevator: 64.37″ wide chain/slat

- Jack: 3.15″ screw, with quick adjustment

Features

Tilting Elevator

Allows the operator to easily feed into troughs, bunks or pasture, and to vary the thickness of the feed-line. The generous overhang eliminates feed being driven over by the wheels, whilst maintaining stability.

1635mm Wide Elevator

The widest elevator on the market, handles any shape or size of supplementary feeds, even the largest of 5’ bales. And the chain/slat design never slips or stretches like that of a conveyor belt. The new design has a 500mm longer elevator.

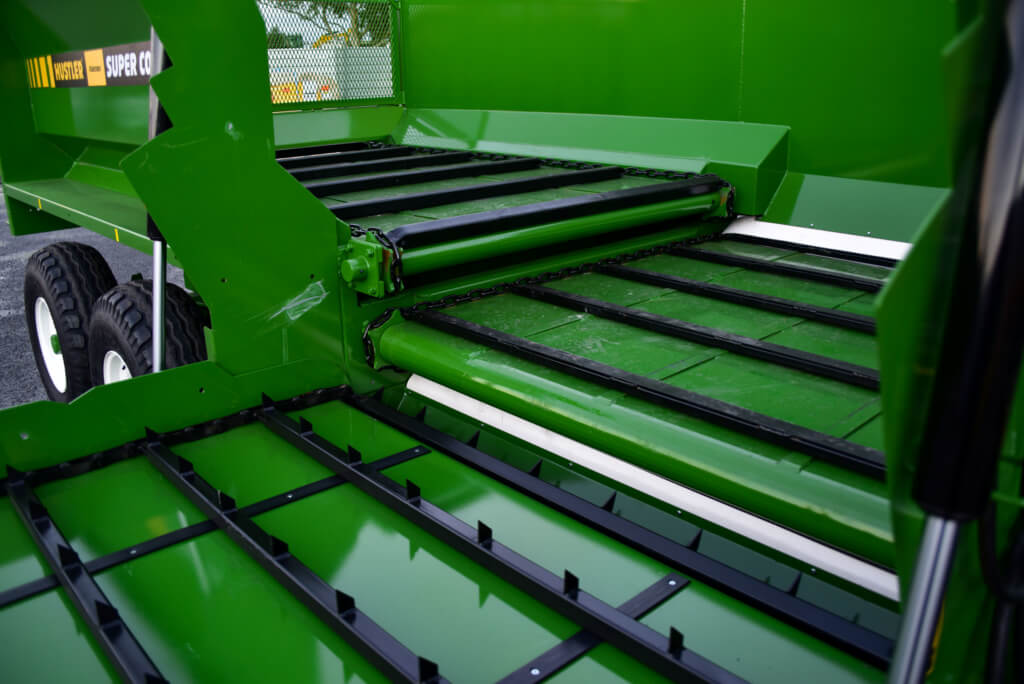

Positive Drive Cross Conveyor

Minimal maintenance, ultra-high breaking strain and a positive drive. Never worry about a derailed or stretched conveyor belt again.

Steel Floor

The all steel floor design, that lasts the life time of the feeder, you’ll never need to worry about a broken board breaking a chain, or rotting out from the exposure to silage juices.

Covered Shafts

New Thermoform floor covers the driveshafts which eliminates any possibility of feed wrapping around the shafts or jamming.

HD Axles

The toughest axle design on the market by a country mile, giving total peace of mind, and eliminating any possibility of downtime.

Large Suspension Travel

The oscillation of the tandem axle allows for travelling over the most rugged terrain with ease.

Folding Tailgate

The new tailgate design makes for quicker and easier operation and stores neatly along the side of the feeder.

Bale Manipulator

The patented bale manipulator aids the loading of large round bales and can be operated from the operators seat on the tractor.

Hose Holder

The built in hose holder keeps hoses neatly stored out of the dirt when unplugged from the tractor.

Protected Hydraulics

The hydraulic valves are nicely protected from the weather, mud and other contaminants. Another built-in downtime saver.

Easy Connection

Only 2 pairs of double acting hydraulic remotes and a trailer plug connection are required to power the Super Comby, and the close off tap makes connecting and disconnecting to the tractor very quick and easy.

Safety Chains

Standard the Super Comby comes with safety chains, for added operator safety both on and off the road.

Forged Towing Eye

The approved towing eye offers 360 degree rotation to protect your tractor and can be locked to simplify hooking up with a quick-hitch.

Heavy Duty Jack

The tough 80mm screw jack with the largest support area, means the jack supports the machine better whilst loading.

Mudguards

Standard the Super Comby is fitted with full length mudguards to protect your feed from contamination and keep the feeder clean.

Welded Body

The fully welded body eliminates the need for bolts or rivets which can loosen when subject to vibration or flex.

Protected Hoses

The hoses on the Super Comby are protected from chaffing, another downtime eliminator.

HD Drives

The simple but heavy duty drives require very minimal maintenance and handle the heaviest of loads.

Load Dividing

The unique load dividing design utilises the entire body for storage capacity, making for more compact and manoeuvrable feeder with better visibility of the load and more weight transferred to the tractor, especially important when operating in the field.

Lower Maintenance

With only one floor runs continuously and the remaining 2 floors move on demand, this substantially reduces maintenance compared to that of a traditional silage wagon.

Load Cell Ready

All new comby wagons come weigh-scale ready from the factory, providing you with a future-proofed feeding solution and easy entry into the world’s best silage feeders. The unique design weighs the entire feeder, whether parked or on the tractor.

Strong RHS Bars

RHS bars are substantially stronger torsionally than angle type bars of same size. We’ve used RHS bar on all floors for strength and reliability.

Finger Tip Control

Standard in-cab electric joystick gives fingertip control over the entire feeder, letting you control the feed row of any feed type and density.

What our customers are saying

“Our first Comby proved that we could feed square bales if we had to buy square bales in dry times, more than adequately, does a great job of feeding out chopped silage, but also means if we’ve got a few round bales we can throw in the wagon and feed them”

Graeme Nicholl, Fish Creek (Australia) - Super Comby/CM106Get your Hustler

Newsletter Signup

Get Out There, in Hustler Country episodes and the latest news