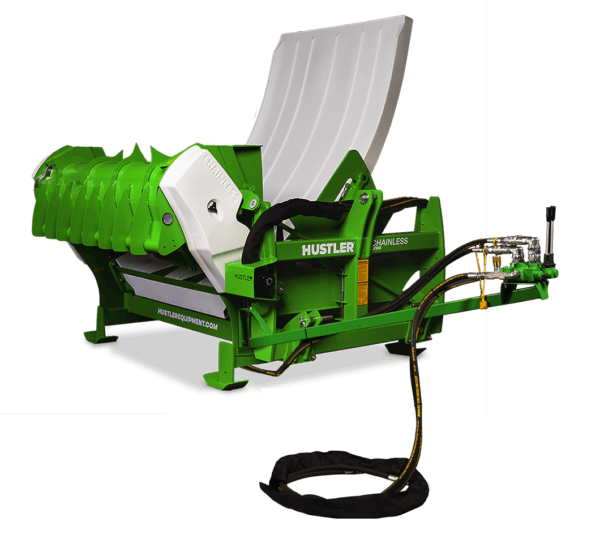

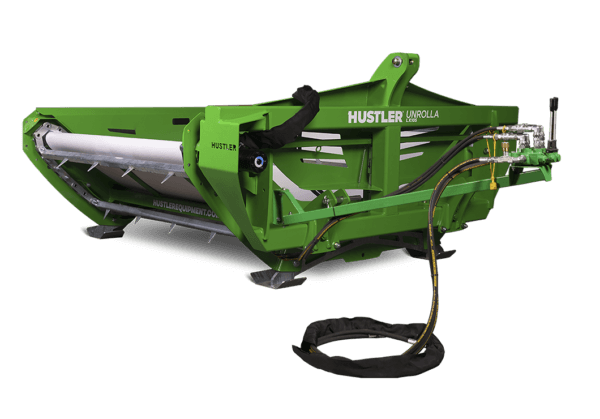

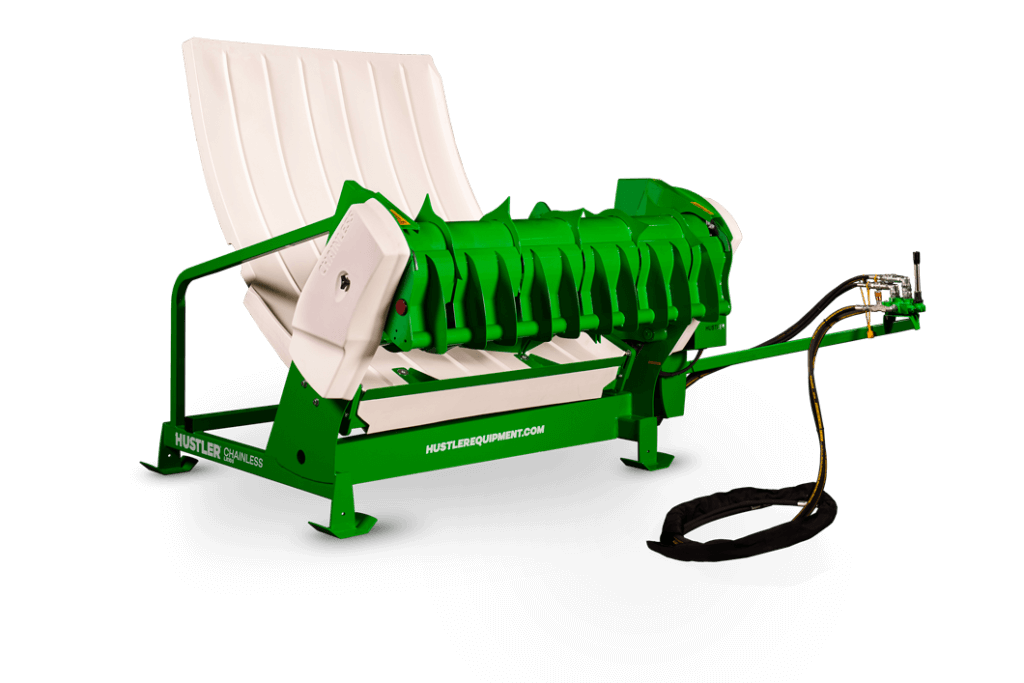

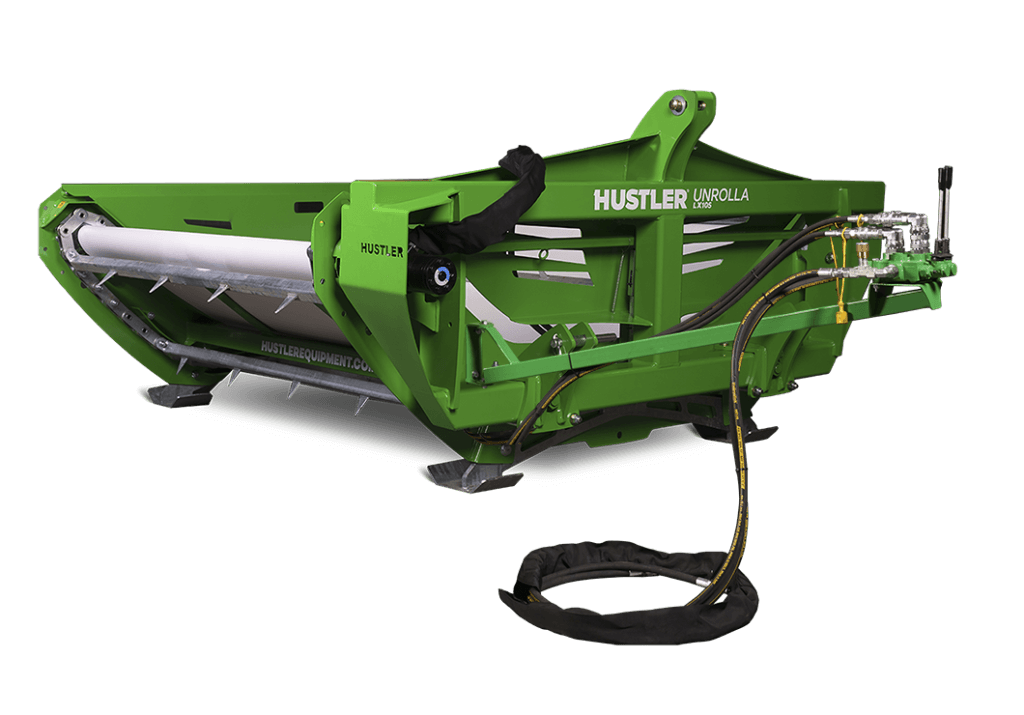

Hustler’s bale processors are the perfect addition to rebaling and hemp processing operations.

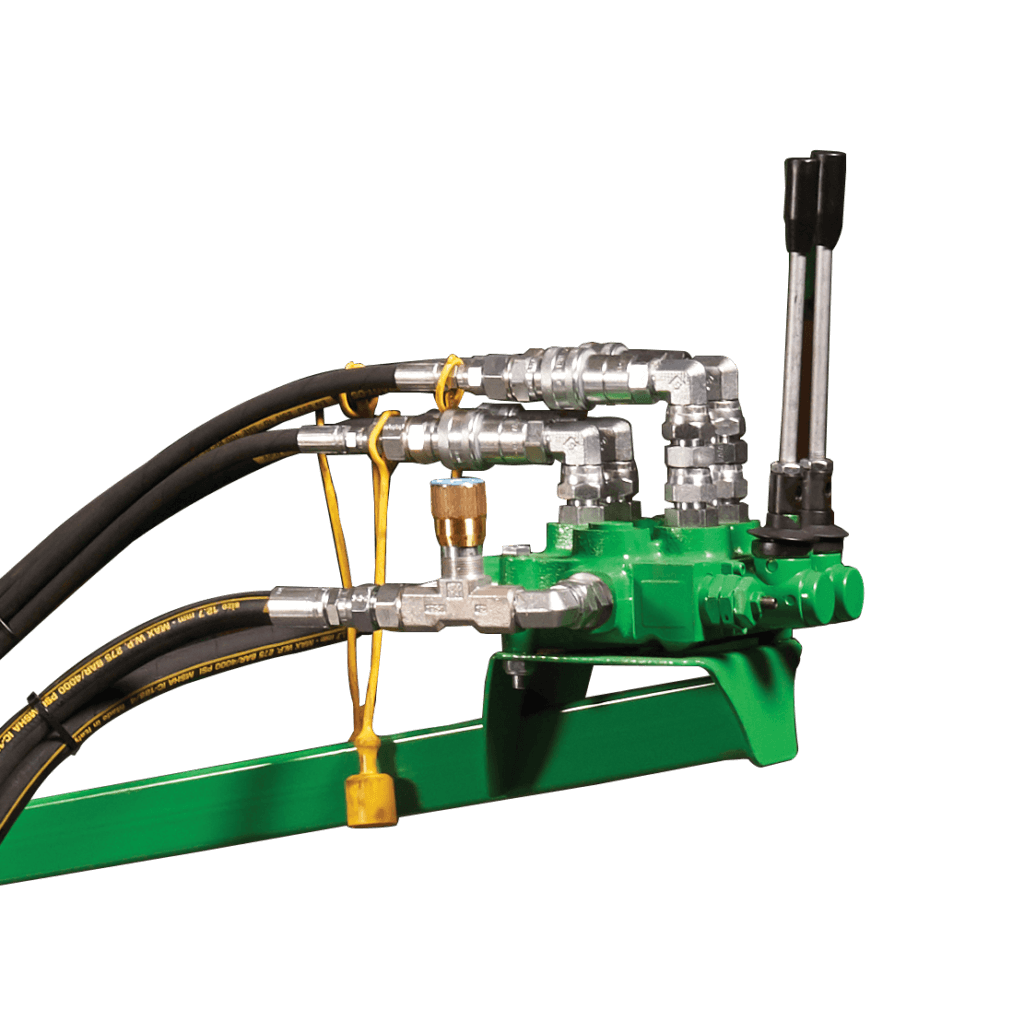

Add an EZ Remote hydraulic control arm to any Hustler mounted machine, these are developed specifically for the use of rebaling, breaking down bales for mixer wagons, and processing hemp, providing huge savings in both time and diesel.

3 REASONS TO REBALE HAY

There are many time, storage and cost saving benefits of producing large round bales in the paddock then converting them to small squares, on demand which are more salable and higher value. It may sounds like just extra effort and time, but rebaling grass and straw proves a profitable trend for many producers.

1. Increase the value of your feed

The average price* for hay in large round bales is $50 to $60 per ton which is very near the cost of production. But when the same hay is put up into small square bales, the price can go up to $150 per ton, especially when marketed to horse owners who often don’t have the time, equipment and storage to make their own hay.

A 800-pound round bale valued at $40 would yield 19 small square bales weighing 40 pounds valued at $3.25 each. This is a $16 gain per round bale (without including the extra costs of the square baling operation).

*depending on the location and the demand

2. Less labour required

A small square baler can be driven at only 3-4 mph while a large round baler can be driven up to 10 mph! Not to mention that picking up the small balls requires additional handling…

You need a crew of about six to bale and stack ten acres of hay in one day. With round bales, three or four people could very easily cover 15 acres in one day.

Rebaling can be a one-man operation if you wanted it to be. With a Hustler Ez Remote coupled to a 100% hydraulically-driven Hustler bale processor, you need only one tractor – the PTO is used to operate the baler while the hydraulics are used to operate the bale processor.

3. Beat Mother Nature

All producers know that harvesting hay can be a tricky business. In years when the weather is unpredictable, you may have only a few days to harvest all your hay fields and it is a true challenge to get the hay cut, dried, raked, and baled and into the barn before wet weather.

Rebaling can be achieved any time of the year, during less busy periods or during winter when the demand for hay is high!

Product Customiser

Select the product, then options and accessories to create your enquiry.