The Hustler’s Combi RX multi feeder wagon proves its value and strength on a Missouri farm

Kent Smith, a Missouri farmer and hardwood flooring businessman, recently purchased one of the very first all-new Hustler’s Combi RX multi-feeder wagons operating in the United States. Strongly built and versatile, this is the machine Kent was looking for to feed his cattle.

The story of Kent Smith starts with his grandfather, Jack Smith, who grew up in the little town of Eminence. Jack Smith was working as a logger and tie hacker in southern Missouri and “he didn’t have two pennies to rub together,” Kent said. In 1947, he founded Smith Flooring, a company now in its third generation of family ownership.

Timber business is “what drives everything” in the Ozark Forest area, but the family decided to “purpose some of that land for growing cattle” Kent explained. Kent is now fully in charge of the beef cattle operation since his father Van Smith passed away suddenly in 2005.

Since then, Kent has fully embraced his life as a farmer. “I feel like I’ve taken off about 10 years of my life sitting in an office wondering about numbers and money, and it’s really nice to be able to get out here where it’s just so beautiful, and walking around the calves every day – out here, outside, is a good one.” Kent admitted.

Although livestock farming and timber harvesting are very different industries, they complement one another, especially in that they share a primary industry asset: land. And “anything you can do to increase efficiency, to maximize your return on any investment that you have out there on the land, is a positive thing,” Kent explained.

“The Combi wagon that we have is amazing”

Kent Smith farms in rugged country, and Kent chose to breed beef cattle that are hardy enough for the area (White Face, Black Baldy…). To feed his herd, he needed a versatile piece of equipment – something that would “feed most anything that I have,” and found the perfect match: the Hustler Combi RX148.

The Hustler Combi RX range is a chain-less rear floor wagon able to feed out literally every supplementary type of feed, including all bale types, shapes and sizes, and any type of loose feed that can be loaded with a loader including fine chop silage, maize silage, root crops, vegetables and more. Its lateral elevator design delivers feed out of the side of the machine to feed into troughs, feed pads, bunks or open pastures.

“It’s easy to load, it’s built very strong, it’s very easy to control”

The loading height of a wagon is often a crucial element since it could narrow the selection of machines that could load into it without damaging the sides of the wagon. With the Hustler Combi RX range, it is possible to use pretty much any front loader of any type (bucket, grab…) to fill it thanks to its low loading height – between 2430 mm (95 inches) and 2650 mm (104 inches) depending on the model chosen.

Once loaded, the Combi wagon is quick and easy to reconnect (no need to connect a PTO), however of course you could load with an extra loader like you would need to when feeding with a TMR (this simplicity allows for efficient use with just one tractor). The operator only needs to get out of the cab twice in total, meaning 66% less cab entry and exit compared to any other 2 or 6 bale capacity bale processor. Whilst similar cab exit/entry is required when feeding with a TMR, both a tractor and a loader are required to do the job.

Once the bale wrap is removed, the hydraulics only need to be reconnected once, which takes only a few seconds. Watch the video below to see how easy the loading and feeding process is with the Combi RX148!

The Combi wagons developed by Hustler are built to last.

- Feed out in the field and on the feed pad with one wagon

The ultra-low center of gravity, combined with the large floatation tires are a game-changer for stability allowing the Combi RX wagon to feed out in the roughest of terrain, the terrain you wouldn’t dare take a mixer wagon on! And Combi RX finds itself just as at home in the field as the feed pad, with a large tilting elevator to place that feed exactly where you’d like it… in the bunks!

- Simple hydraulic drive – with out the need to a PTO shaft!

Yes, the simple design of Hustler’s Combi range is powered by hydraulics for safety, reliability, and lower power consumption. And with the oversized 12,000 lb roller chains to the high tensile sprockets, there are no wearing parts to buy or replace for the life of the feeder! And it handles all types of feeds including balage, silage, root crops or anything else you can load in it. The powerful hydraulic ram-powered pusher blade ensures even the ugliest of bales are no contest!

- Massive drawbar clearance

The drawbar design offers great clearance and a major advantage (far superior to any wide-angle PTO shaft) in maneuverability, making life easier for operators in tight lanes and gateways. This reduces the possibility of damaged gate posts or machines due to operator error. Kent Smith’s Combi RX148 has a turning circle of 7.8 m (25 ft) compared to 20.8 m (68 ft) for the equivalent size wagon.

- Impact-resistant floor

The unique heavy-duty 15-mm (3/5″) thick puck board rear floor is slippery, durable and extremely tough, it handles the impact of heavy beets landing on it without damage.

… and the list goes on!

Recently Kent Smith found himself sliding backward down an icy hill, jack-knifing his Combi wagon. Thinking it was going to be out of service for weeks, turned into a $10 trip to the store thanks to Hustler’s design and strength. “This thing is built like a tank,” Kent explained in the short video below.

“It takes minimal inputs on the tractor, just two sets of couplers of hydraulics – and you can run everything on it!”

Running a machine on 100% hydraulics has numerous advantages. For the safety of the operator first with no dangerous PTO to connect and disconnect. Hydraulics also need less horsepower and less fuel to achieve the same result. Hydraulic also means less maintenance overall. As Kent said, “you don’t get much simpler than a simple set of chains and a hydraulic cylinder”.

And it’s simple to use! The Hustler Feed Control has two operation modes for silage and bales providing the operator with semi-automated control when feeding silage or full control over each floor for more versatility when feeding bales.

“I can throw anything into this box and it’s going to come out and be fed the way I want it to, in a nice line down the field where the cattle aren’t stomping every bit of it into the mud”

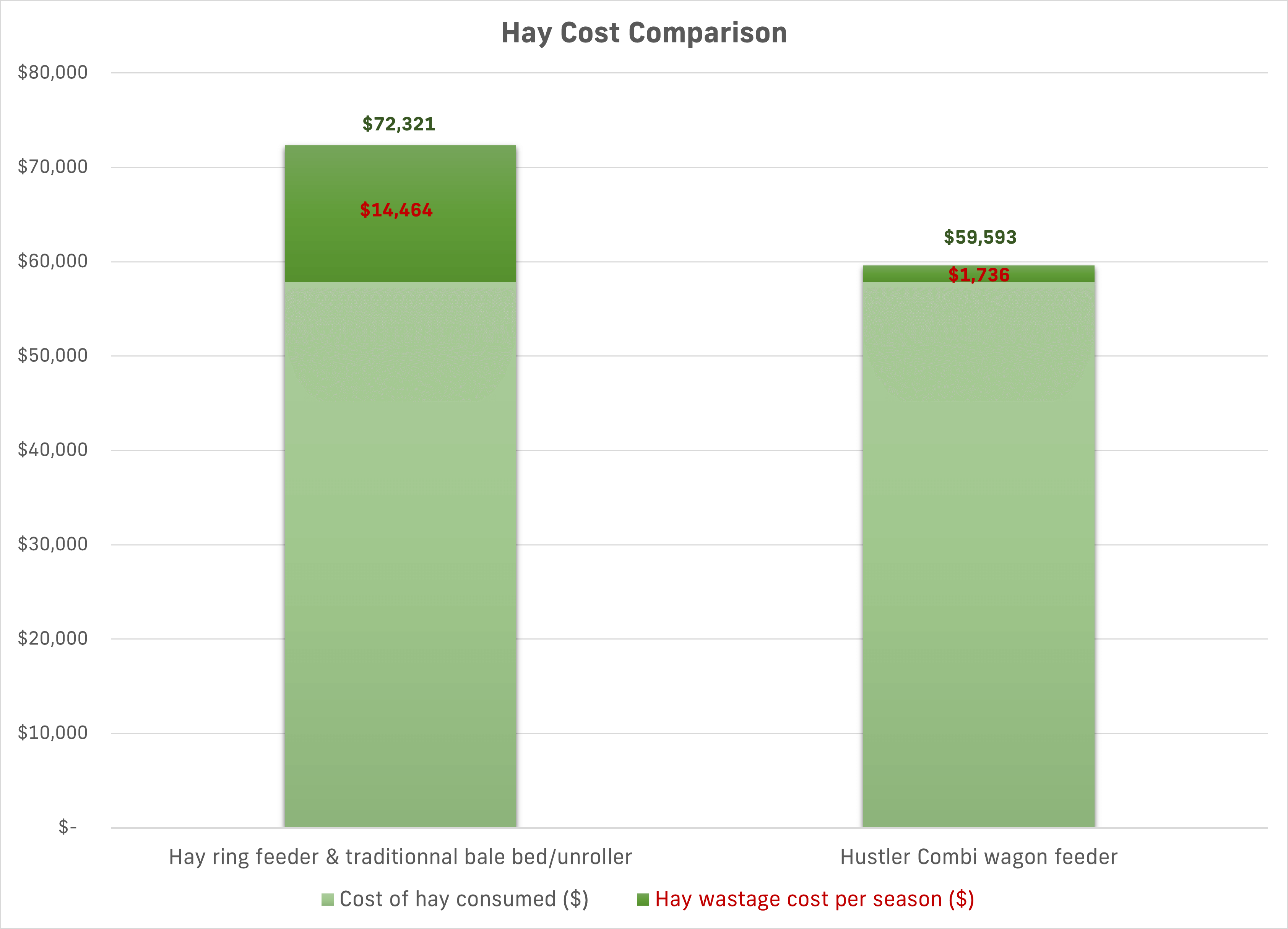

And at last but not least, Kent Smith is able to achieve huge hay savings using a Hustler Combi wagon feeder compared to a traditional hay ring or a bale bed/unroller. Many ranchers have the impression that purchasing feeding equipment is expensive and unnecessary because of the higher initial capital outlay. However, taking into account the long-term losses including additional labor costs, wastage, damage to pasture and environmental risk, purchasing an efficient feeding system such as the Hustler Combi wagon will turn out to be more economical.

Below is the breakdown of hay costs for Kent Smith’s ranch.

By owning a Hustler Combi feeder, the ranch now feeds 927,002 lb (413 tons) of hay per year, compared to the 1,124,993 lb (502.2 tons) of hay fed per year with its previous system. This reduction in hay waste, close to 20%, translates to saving over $12,500 per season for Kent Smith. It allows him to recoup his investment in just a few years.

And do you want to know more about Hustler’s awesome products? Contact us today, you’ll be glad you did!