This model is now replaced by the Chainless SX105 Rebaler

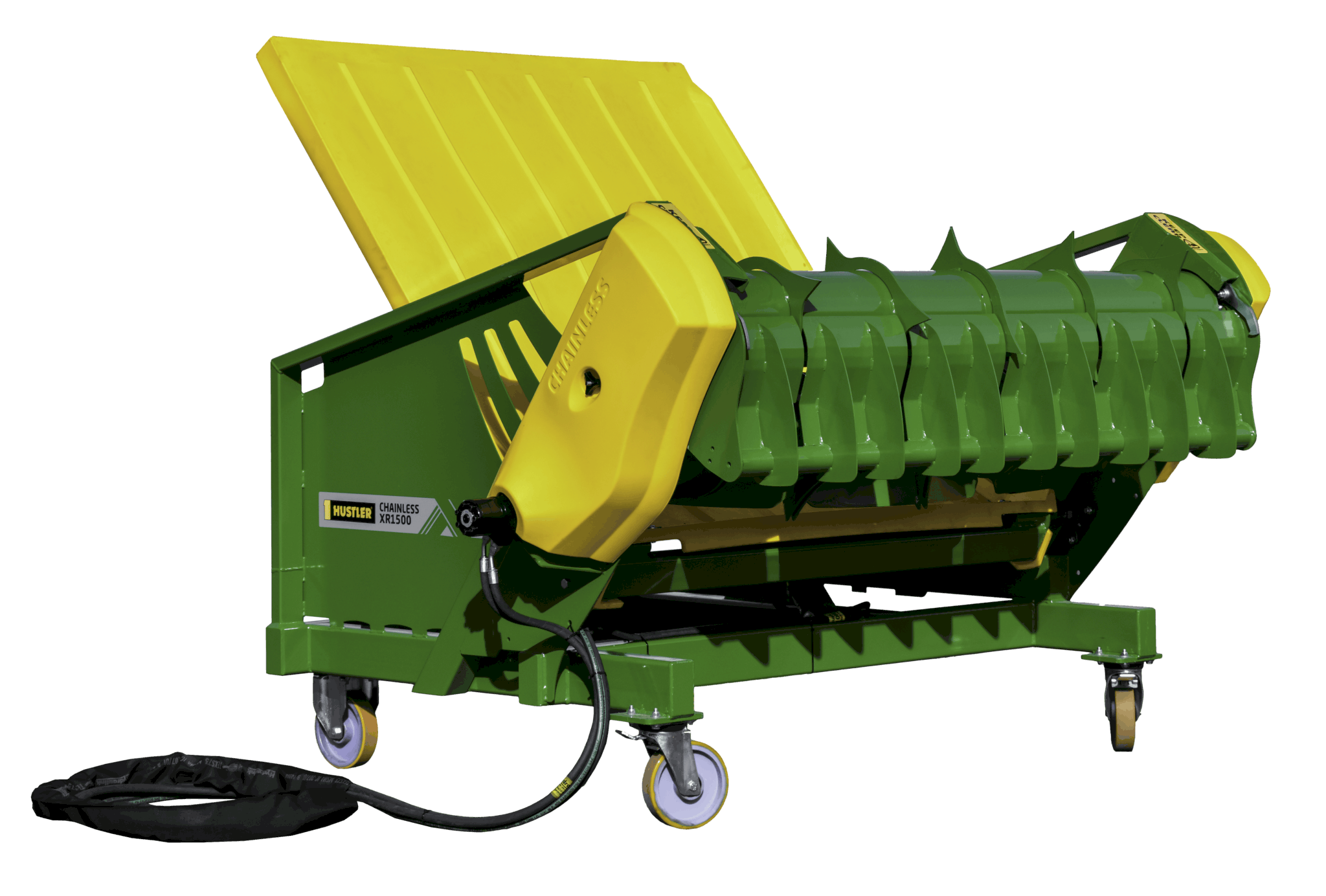

The Chainless XR1500 is a stationery bale processor, developed specifically for the use of re-baling and breaking down bales for TMR Mixer’s. The Chainless XR1500 efficiently teases apart large round bales in less than 2 minutes which provides huge time, cost and diesel savings.

Benefits

- No feed chains, no PTO = extremely low maintenance. Less wear, longer life and low power requirement due to superior Hustler engineering.

- Will easily de-bale round bales, any size. The Chainless can handle any type of bale that you have on hand – balage, hay, straw, lucerne, alfalfa, etc.

- Bales are teased apart by variable rotors. The Chainless lays down a fluffed-up windrow which makes rebaling easier and TMR mixing quicker .

- Simple to operate hydraulic control

- 2 year warranty. Hustler’s stamp of quality, backed up by Hustler’s accredited dealers

Features

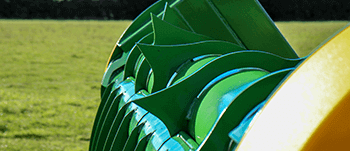

Rotor teeth

Many hours of research and development have gone into the shape of the teeth to makes them clean easier, and have more aggression on tight bales. The XR15000 has 5 teeth per rotor to provide extra grip on soft bales.

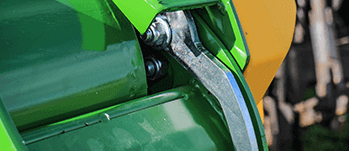

Quick release wiper

A quick release latch releases the wiper panel for easy cleaning.

Axial rotor

The addition of a new Axial Rotor with centralising paddles keeps the bale positioned in the centre of the feeding chamber to minimise wastage and provide better grip on soft bales.

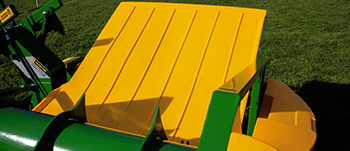

Sandblasted, wet coat finish

New sandblasted finish and improved paint system means your new Chainless XR1500 will look smarter for longer.

Protective covers

Transmission covers protect against mud and debris getting at the heavy duty drive system which reduces maintenance.

FeedGuide

The clear, easy to read platform height guide shows starting positions for various bale types making it easier to use for all operators.

Feed control

Infinite variation in feed control, allows you to feed thick for cattle, thin for sheep to increase the palatability for your stock.

Rotors

Top rotor turns 3 times faster than bottom rotor – excellent teasing action provides fluffed up windrow reducing wastage > No troublesome feed chains to jamb, stretch or break > Fully enclosed drive transmission protected from damage > Paddles for handling even the sloppiest of bales > Spiral timed teeth makes for smooth running.

Teeth

Rotor teeth release the feed off the taper at the correct point. They’re also self cleaning so hay doesn’t get jammed between the timed rotors.

Low maintenance drive

400cc hydraulic motor. Outboard bearing blocks are in a good position to keep clean and greased. Automatic drive chain tensioners mean no adjustment are necessary. Self aligining bearings are free running and protected behind drive covers.

Hypaflow wiper

The Easy Clean Hypaflo Wiper Panel minimises blockages and ensures that hay drops outside the wheel tracks to avoid being flattened into the mud. A quick release latch releases the wiper panel for easy cleaning.

Adjustable platform height

Infinitely variable bale pressure control from inside the cab allows you to feed out the tightest bale cores or the sloppiest of bales > Built in height guides for easy feeding > Safety latch so operators can’t drive out while platform is up > For different bale types blank bars or bars with more aggressive teeth are available.

Polyethylene floor

Hustler’s proven polyethylene platforms with ribbed design keeps bales tracking straight and with 30% less friction than steel it reduces drag on the bale which makes feeding out sticky bales easier and it will never corrode. Polyethylene is impervious to UV, non corrosive, and slippery to reduce drag and drive power, it is easily repairable and very shock resistant. Built-in bale guides help keep bales tracking straight.

Get your Hustler

Newsletter Signup

Get Out There, in Hustler Country episodes and the latest news