- Home

- Bale feeders

- Mounted Bale Unrollers

Mounted Bale Unrollers

The toughest, simplest and most versatile round bale feeding solution.

The toughest, simplest and most versatile round bale feeding solution.

Easier to use than any other type chain feeders on the market today. Being the most innovative, with 6 unique features you won’t find on any other bale feeder that makes it easier to use, more versatile, and saves your precious time. Recommended for farms feeding 50-800 bales each year, the self-loading 3-point linkage mounted feeder is suitable for feeding out all but the tightest of round bales and baled silage, loose silage, maize, fodder-beet and more.

Key Benefits

Snaplox - Connection System

The LX105 Unrolla Snaplox auto connect/disconnect hands-free loading system, saves you time, saves you having to tug on a rope to disconnect, and saves you from twisting your back. It’s fail-safe, fast and operates naturally.

Toughest Chains

Toughest chain and floor bars on the market is bullet-proof and lasts the entire life span of the feeder. Super strong roller chains with the combined strength of 24,000lbs, with tough 40mm x 40mm zinc-plated bars. Bars are bolted to the chain, a stronger and more easily replaceable system.

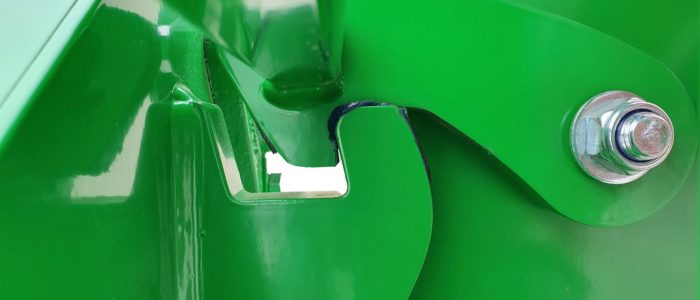

Covered Drive Bearings

The LX105 Unrolla has covered drive bearings to keep the dirt out, extending bearing life.

Polyethylene Floor

Tough new Thermoform fully enclosed polyethylene floor with covered drive shafts which eliminate wrapping. It’s non-corrosive, impervious to UV, slippery, easily repairable and very shock resistant. Fully enclosed – no wastage of expensive feed. The long bed can take 5’ long bales.

Low Maintenance Bearings

Just 4 grease nipples, is all it takes to maintain the mounted round bale unroller, that’s because instead of bushes we use longer lasting, fully sealed block bearings, mounted outboard to keep them clean and free of damage from acidic silage juices. We’ve also added bearing covers which prevent debris from causing damage.

Flexible Design

Do you operate in barns, outdoors, on steep country, with a tele-loader, supplement with loose silage or fodder beet? With the flexible configuration of the mounted round bale unroller, your new feeder will suit all of the above. No other feeder allows this level of flexibility which gives you peace of mind, should you want to change the way you operate. You won’t need to change your feeder.

3PTL or Loader Mounted

The LX105 Unrolla is 3PTL or loader mounted, utilizing a new headstock design with bolt-on brackets, you get to choose if you want it mounted on the front or rear of a tractor or loader, and it can be offset to allow more tyre clearance when feeding into bunks or troughs.

Multi-Hitch option

Our Hustler multi-hitch simplifies connection, allowing the LX105 mounted bale feeder to be connected to the front loader or 3 point linkage in minutes without the need for any tools.

Product Customiser

Select the product, then options and accessories to create your enquiry.

LM105 Mounted round bale unroller

LX105 Mounted round bale unroller

Includes as standard equipment:

- Snaplox Hands-Free Auto Latching System

- Front End Loader Capable

- Removable Rear Fence

- Fixed Front Fence on Headstock

- Removable Lower 3PT Linkage Mounts

- Hydragrip QRC Hose Grips

- Bearing Covers

Options and Accessories

Rear / Front Fence

Optional Front / Rear fences are available for all mounted unroller models and allow connection at either end without the need to remove the fence. It eliminates wastage by preventing feed from falling out.

Rear / Front Fence

Optional Front / Rear fences are available for all mounted unroller models and allow connection at either end without the need to remove the fence. It eliminates wastage by preventing feed from falling out.

Enquire now

Your selection

Selected product

Selected Options and Accessories

What you'll get

- Access to a dedicated Hustler expert

- No Obligation Quote

- Your Quote Within 24 Hours