- Home

- Bale feeders

- Chainless Rebalers

Chainless Rebalers

The Chainless SX105 efficiently teases apart large round bales in less than 2 minutes which provides huge time, cost and fuel savings

The Chainless SX105 bale feeder is a stationery processor for use in rebaling operations and hemp processing

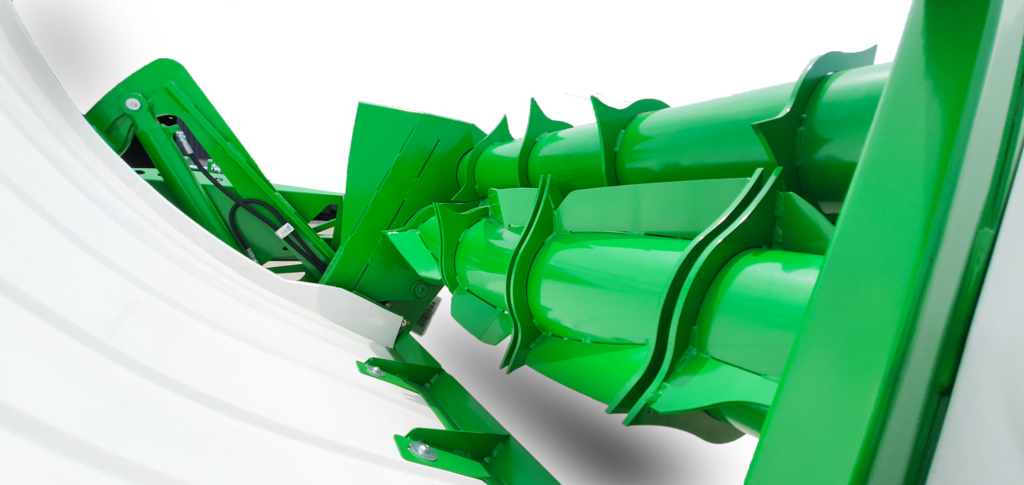

Developed specifically for the use of re-baling, breaking down bales for mixer wagons, and processing hemp, the Chainless SX105 efficiently teases apart large round bales in less than 2 minutes which provides huge time, cost and fuel savings.

Key Benefits

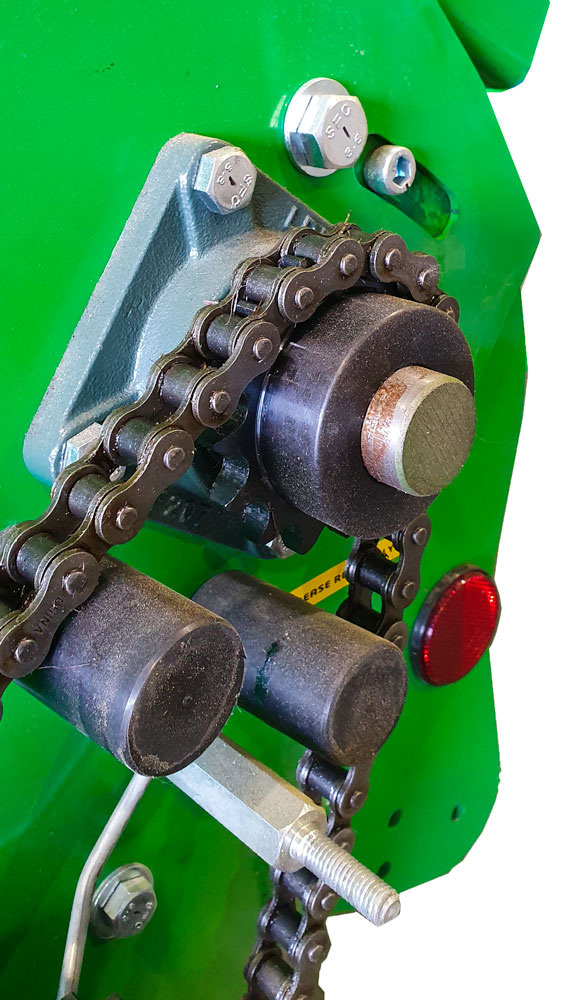

No Feed Chains, No PTO

Extremely low maintenance. Less wear, longer life and low power requirement due to superior Hustler engineering.

Rebale Any Bales

Will easily de-bale round bales, any size. The Chainless can handle any type of bale that you have on hand – balage, hay, straw, Lucerne, alfalfa, etc.

Variable Rotors

Bales are teased apart by timed rotors. The Chainless lays down a fluffed-up windrow which makes re-baling easier and TMR mixing quicker.

Easy To Use

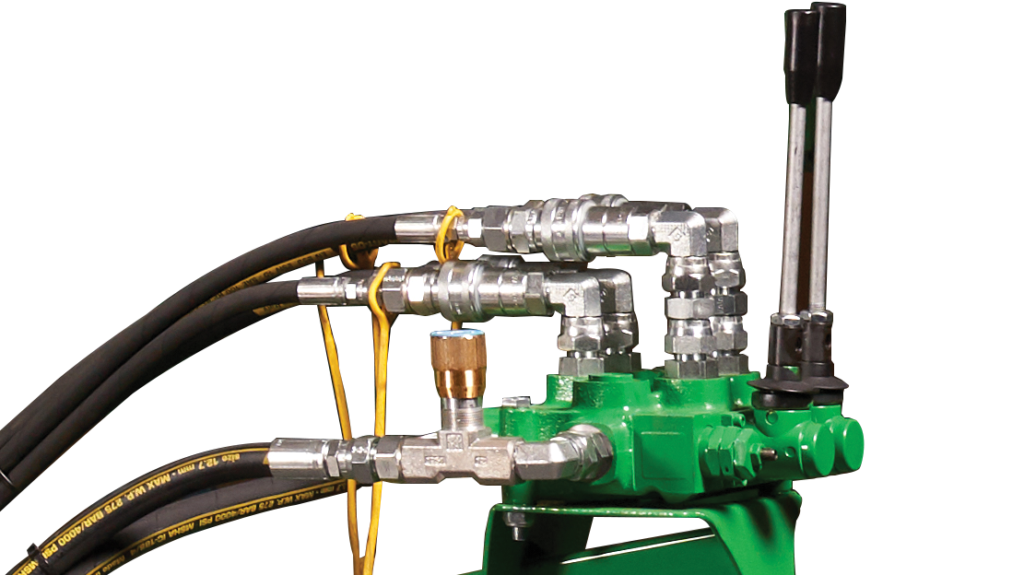

The simple hydraulic design makes it very easy for any operation to master very quickly.

Product Customiser

Select the product, then options and accessories to create your enquiry.

Chainless SX105 Rebaler

Options and Accessories

Castor Wheels

Large mounting pads allow the SX105 to be easily mounted on optional castor wheels.

Enquire now

Your selection

Selected product

Selected Options and Accessories

What you'll get

- Access to a dedicated Hustler expert

- No Obligation Quote

- Your Quote Within 24 Hours