Hustler Global

This model is now replaced by the Mounted Unrolla LX105 Round Bale Processor.

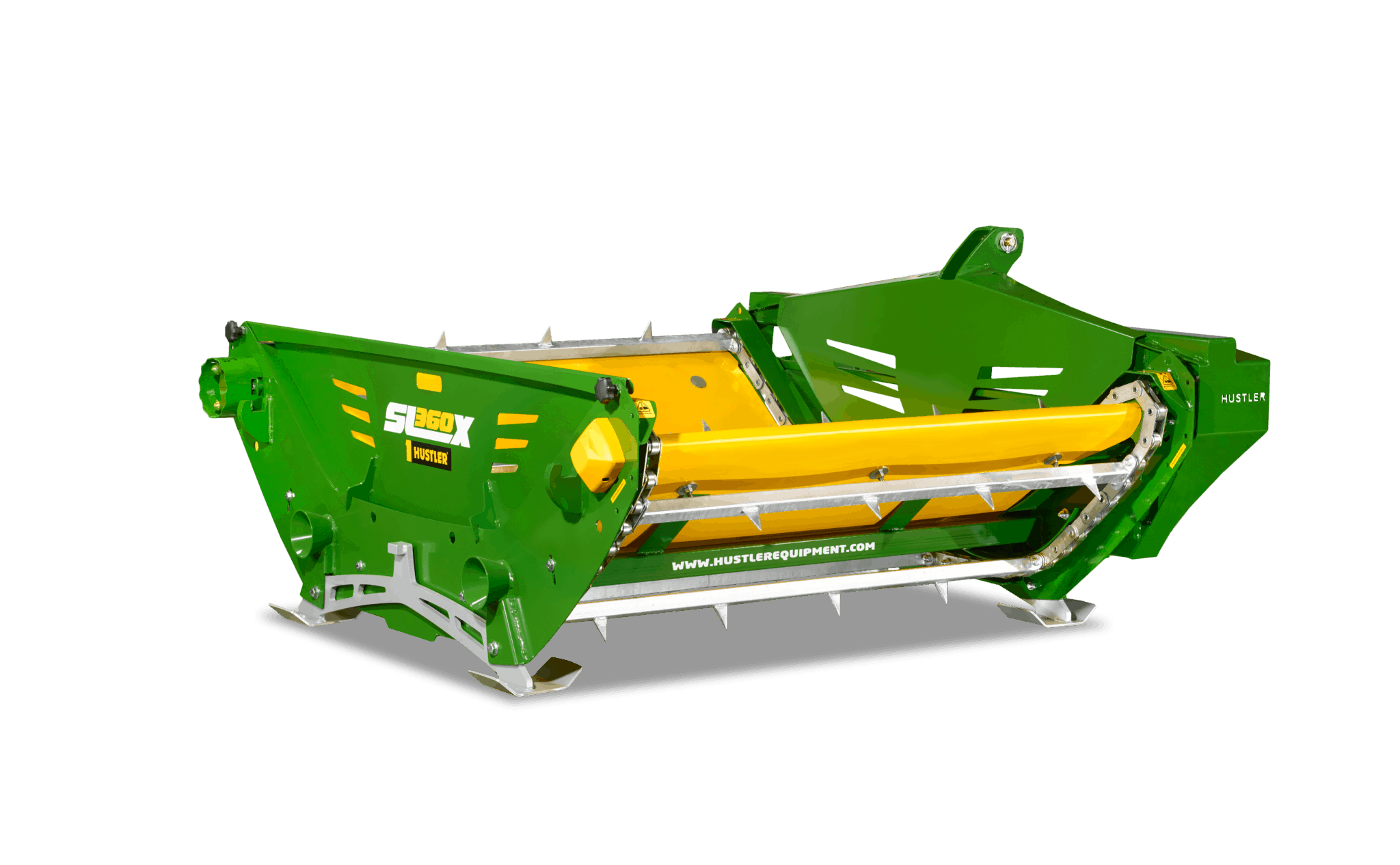

The all new SL360X is easier to use than any other type bale unroller or hay processor on the market today. It is also the most innovative, with 6 unique features you won’t find on any other bale processor that makes it easier to use, more versatile, and saves your precious time. The self-loading design can be front loader or 3-point hitch mounted and is suitable for feeding out all but the tightest of round bales and baled silage, loose silage, maize, fodder-beet and more…

Benefits

- The Snaplox auto connect/disconnect hands-free loading system saves you time, saves you having to tug on a rope to disconnect, and saves you from twisting your back. It’s fail-safe, fast and operates naturally.

- Toughest chain and floor bars on the market, is bullet-proof and lasts the entire life span of the feeder. Super strong roller chains with the combined strength of 24,000lbs, with tough 1.58″ x 1.58″ zinc-plated bars. Bars are bolted to the chain, a stronger and more easily replaceable system.

- Tough new Thermoform fully enclosed polyethylene floor with covered drive shafts which eliminate wrapping. It’s non corrosive, impervious to UV, slippery, easily repairable and very shock resistant. Fully enclosed – no wastage of expensive feed. Long bed can take 5’ long bales.

- Low maintenance. Just 4 grease nipples is all it takes to maintain the SL-360X, that’s because instead of bushes we use longer lasting, fully sealed block bearings, mounted outboard to keep them clean and free of damage from acidic silage juices. We’ve also added bearing covers which prevent debris from causing damage.

- Flexible design – do you operate in barns, outdoors, on steep country, with a tele-loader, supplement with loose silage or fodder beet? With the flexible configuration of the SL-360X, your new feeder will suit all of the above. No other feeder allows this level of flexibility which gives you peace of mind, should you want to change the way you operate. You won’t need to change your feeder.

Specifications

- Bale size round: 4’ X 4’ – 6’ X 5’

- Bale size square: requires optional side bars

- Bale weight: up to 2760lb

- Unit weight: 1100lb

- Tractor size: 60hp +

- Capacity: 1 bale

- Hydraulics required: 1 X double-acting, 8-16 gal/min, 2250-3000 psi

- Loading: Self-loading

- Size (L x W x H): 82.3″ x 80.63″ x 41.1″

- Chain: 24,000lbs load rated roller chains

Features

Snaplox

Auto connect/disconnect hands-free loading system saves you time, saves the frustration with tugging on a rope to disconnect, and saves you from twisting your back. It’s fail-safe, fast and operates naturally.

Strongest Bars

Floor bars are 4-5 times stronger torsionally than angle type bars of the same size. We’ve bolted them to the chain which is stronger and for different bale types, blank bars or bars with more aggressive teeth are available and can simply be bolted on in a matter of minutes without breaking the chain.

Loader Mounts

The headstock design allows for optional loader mounts to be bolted direct to the frame, allowing the feeder to be operated on a loader or telehandler. This provides hay and fuel savings when using the SL-360X for feeding into bunks, TMR mixers, and hay rings.

Added Versatility

Add an extra fence to the options and you can feed loose silage, maize, fodder beet, etc, loaded with the bucket on your front loader and connect-n-feed from either end of the cradle.

Covered Shafts

New Thermoform floor covers the driveshaft’s which eliminates any possibility of feed wrapping around the shafts or jamming.

Sideshift

The bolt on lower hitch mounts allows for the feeder to be off-set by 180mm in either direction, another unique feature that allows operators to distribute the feed closer to the head-bails and stock in barns eliminating double handling of the feed saving your time. The off-set feature works for both 3 point linkage and most loader mounts.

Tynes that pierce the bale

We’ve used specifically designed forged bale spears which pierce the bale rather than pushing it and are longer which reduces bale sag even with the wettest of bales, another innovation from Hustler.

Toughest Chain

Toughest chain on the market. Zinc plated chains rated to 24,000lbs with the larger diameter rollers and pins make our chain drive system almost twice as strong as our competitors. And the greater surface on each roller pin increases chain life because they can’t stretch or snake.

Thermoform Floor

The new single piece fully enclosed floor reduces feed waste and will never corrode. Being polyethylene it is slippery with 30% less drag compared to steel which makes feeding sticky silage or wet bales easy.

Ultra-low Cradle

Our ultra-low cradle design with removable fences makes for easy loading should you not have much lift height on your tractors hitch, and lets you customise the feeder to your preferences. The longer spears also make loading easier, by reducing sag.

Chain Tensioners

Are built into the design, should you ever need to adjust the pre-set chain tension.

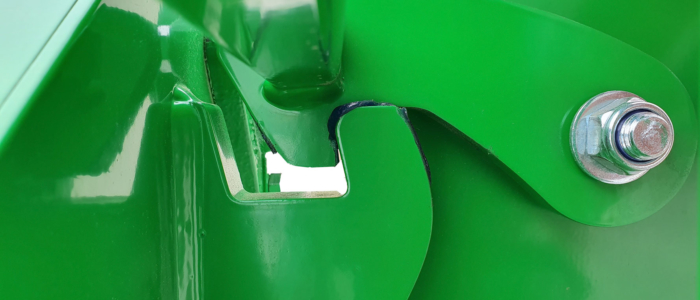

Dual Latches

High mounted connection latches on both sides of the feeder take the load off the cradle, which removes any load from the bale spears. This provides a more reliable, positive connection to handle the heavier bales it has been tested to handle.

Connect Either End

To simplify loading and connecting, we’ve allowed you to connect or load from either end of the cradle. This also allows operators to switch the direction the bale is being unrolled without unloading the bale, which makes feeding tighter bales on both sides of the passage in single access barns much quicker and easier.

Covered Drive Bearings

Bearings outlast bushes, require less grease and self-align to the shafts. These 3 reasons are why farmers prefer our double sealed heavy duty 4-bolt bearings with trash shields over the bushes. We mount them outboard of the feeding chamber, which prevents silage juices from accelerating wear and we’ve now covered them to eliminate debris from causing damage.

Enclosed Sprockets

Our 6 tooth sprockets are made from Bisalloy (the same material used in a bulldozer blade) so they last forever. With smaller diameter sprockets less torque is required to drive the chains, giving more drive power for tough bales. Designed so it is impossible for the chain to jump off the sprockets, this saves you downtime in the field.

Bale Chamber

Fully enclosed front and rear bale reduces feed falling out whilst travelling and an optional fence can be added to each end, should you want to feed loose silage or fodder beet. The bale is held securely in the chamber on the steepest of terrain.

Large Rear Fence

To pull the bale against – makes loading with a front loader easier and the bale is held securely in the chamber on even the steepest of terrain.

Protected Drive

The drive coupling is protected to eliminate hay from jamming it when connecting, and the hardened drive connection which has been proven on thousands of machines is built to last.

Unequal Length Tynes

We’ve made one tyne longer than the other for quick and easy alignment when reconnecting the cradle. You’ll only need to line up one tyne, then back straight in.

Protected Motor

We’ve protected the motor from coming into contact with the tractor tyre, which can save you costly downtime and repairs when your tractor has short linkage arms.

Single Level Control

Enables the SL-360X to feed bales out to the left or right and gives precise control of the feed rate. The SL-360X can be connected from either end, which allows you to swap sides should you have a tight bale and want to feed on a particular side of your barn.

Get your Hustler

Newsletter Signup

Get Out There, in Hustler Country episodes and the latest news