- Home

- Bale feeders

- Trailed Chainless Bale Feeders

Trailed Chainless Bale Feeders

Self-loading, suitable for feeding out any bale, round or square

The top of the range trailed Chainless double bale feeder.

The Chainless trailed square and round bale feeders are self-loading, suitable for feeding out any bale, round or square, and it maximises feed use. Designed for medium to large operations. A Chainless trailed bale feeder minimises feed waste by feeding out into narrow windrows to make the feed more accessible to animals and all but eliminate damage from hoof trampling, manure spoilage, and animals laying down on the feed. More efficient use of power, savings on machinery investment and faster bale feeding all add up to impressive fuel economy – made possible by the hydraulic drive system at the heart of every Hustler Chainless trailed bale feeder.

Benefits

Feeds any Bale Type Shape or Size

The Chainless Trailed Bale Feeder is the most versatile Bale Feeder, it will feed out any bale round, square, tight, soft, short, long, dry and wet bales with ease.

Chainless

No troublesome feed chains is a key advantage for – Reliability, lower maintenance and quieter operation, the teasing action of the rotors uses feed more economically because it is easier for the cattle as they can eat it because it is fluffed up. The Chainless can effectively feed out any bale type in both round or square. Chainless is a virtually silent feeding operation which means your stock will be more comfortable.

Total Control 2 Loading System

This gives you total control overloading the bale. The simple, reliable and fool-proof single cylinder design of the Hustler loading system is safer than other loading systems and allows unwrapping of the bale above the feed cradle, reducing waste. The Hustler loading system can be reversed if the operator decides not to load that bale. It also has more support area for soft or square bales. The Chainless square and round Bale Feeder have more leverage, stronger design and larger 1.5-tonne capacity.

Easy Clean Hypaflo Wiper Panel

The newly developed wiper panel that clears the hay from the rotors better. It has a new quick release latching system for releasing the panel to clean out any hay.

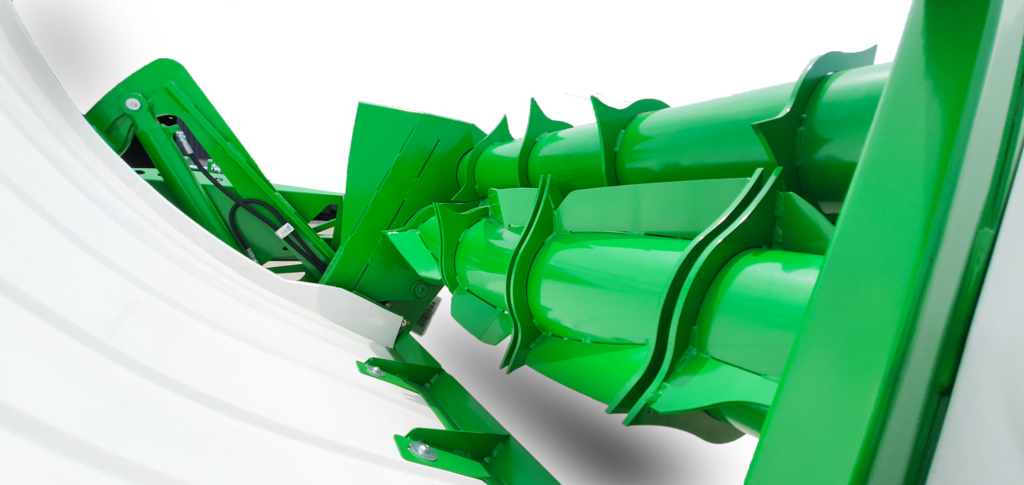

New Rotor

The New Rotor shape has better penetration on tight bales and the shape cleans sticky bales better. The new Axial Rotor centralizes the bale in the feeding chamber so that there is less wastage. It has more grip on sloppy, rotor cut bales which makes feeding them out easier and more efficient. The larger bale chamber makes it possible to feed out a wider range of bales, and also makes using the TX205 trailed bale feeder very simple for operators of all skill levels and reduces the need for platform adjustment

Time-Saving Features

Loaded with time-saving and money-saving features such as; QRC Grips, Drawbar hose holder, biggest stub axles on the market, Loadial loading indicator, Feedguide built-in platform height guide and Hustler’s stamp of quality, full 2-year warranty, and much more.

Stability

The Chainless Trailed Bale Processor with its low centre of gravity and wide wheel track makes it the most stable Bale Feeder on the market when in operation adding peace of mind.

Product Customiser

Select the product, then options and accessories to create your enquiry.

Chainless TE205 Round & Square 2 Bale Feeder

Chainless TX205 Round & Square 2 Bale Feeder

Includes as standard equipment:

- Uprated 1.5 ton capacity

- Loading Tyne Position Indicator

- Quick Release Wiper Panel

- String Box

- Wide Wheels

Options and Accessories

Loading Tyne Position Indicator

The new easier to read loading indicator makes loading any bale simple: line up the indicator to correct bale position, back in and load.

Quick Release Wiper Panel

The newly developed Easy Clean Hypaflo wiper panel that clears the hay from the rotors better. It has a new quick-release latching system for releasing the panel to clean out any hay.

String Box (Trailed bale feeders)

Our massive new twine box keeps your wrap and string out of harms way and your tractor cab clean and odor-free. Big enough to hold fencing standards, knives and anything else you need on the job.

Extra Loading Tyne

Adding extra loading tynes to your trailed bale feeder is ideal for handling larger square bales that require additional support. As the tynes are a bolt-on option, you can retrofit them on any trailed models you use.

Platform Extension

Optional platform extension available for 8’ long square bales.

Combi Spread - Causmag Spreader

Attachment can be fitted to any bale feeder, Silage wagon or Combi Feeders and has been designed especially for spreading causmag, lime flour or minerals directly onto the row of feed.

Extra Loading Tyne

Adding extra loading tynes to your trailed bale feeder is ideal for handling larger square bales that require additional support. As the tynes are a bolt-on option, you can retrofit them on any trailed models you use.

Platform Extension

Optional platform extension available for 8’ long square bales.

Enquire now

Your selection

Selected product

Selected Options and Accessories

What you'll get

- Access to a dedicated Hustler expert

- No Obligation Quote

- Your Quote Within 24 Hours