Chainless Rear Floor Feedout WagonComby PR

This product range is now replaced by the Combi RX multi-feeder range.

The PR Series Comby feeders eliminate the need for floor chains in the main load area increasing capacity in a more compact size. Capable of feeding every type of supplementary feed you can lay your hands on, including all bale types, shapes and sizes. And any type of loose feed including fine chop silage, maize silage, root-crops, vegetables and more. Available in 2 sizes: COMBY PR 1350 – 13.5 – 16.0m3. COMBY PR 2100 – 21.5 – 24.0m3.

Benefits

- VERSATILITY – If you’re feeding a combination of bales, silage, root-crops or any other supplementary feed, then the Comby PR is the only multi-feeder you’ll need. Comby PR is able to feed all types, shapes and sizes bales including straw, hay and baled silage, fine chop silage, maize silage, root crops and literally any type of feed you can lay your hands on. The unique elevator design delivers feed out of the side of the machine allowing you to feed into troughs, feed-pads, bunks or open pasture

- CONTROL – The unique design of the Comby PR provides the operator with more control and visibility of the task at hand. More control over the feed-row lets you maximise your feed by varying from light for sheep and deer to the heavier row for feeding cattle and anything in between with no big clumps left in the pasture. The ability to see the entire load from the comfort of your seat puts you in control of feeding

- RELIABILITY – The combination of a tough, well-proven design with the design smarts of the unique load dividing system reduces loads and stresses on drives, motors, shafts and the floor extending the working life, reducing maintenance and less to wear out which lets you spend more time feeding out, less time in the workshop. The PR series has a single hydraulic ram delivering 12000kg pushing power, which eliminates 1 set of floor chains reducing maintenance and the mesh tail-door gives good visibility.

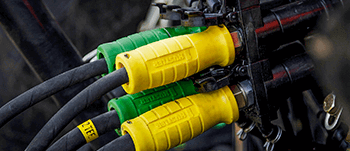

- EASY TO USE – With a simple Joystick Control Feeding System only 2 double acting hydraulic outlets are required to operate the entire machine. Elevator, loading forks, main floor and cross floor giving you more control, from your fingertips. You have full control of the feed material and the two piece pusher blade allows easy rear loading. The low loading height simplifies loading and the wide design makes it the most stable unit on the market.

- ACCURATE FEED DELIVERY – All Comby feeders now come load cell ready as standard, which allows you to add the weighing option when it suits your operation so you can accurately measure the correct amount your herd needs, reducing waste and increasing the performance of your farm.

Specifications

| CAPACITY | PR600 | PR1350 |

| ROUND BALES 4′ DIAMETER | 4 – 5 | 4 – 5 |

| SQUARE BALES | 6 – 15 | 6 – 15 |

| BULK SILAGE LEVEL LOADED | 6m3 | 13.5m3 |

| BULK SILAGE LEVEL HEAPED LOADED | 8m3 | 16m3 |

| MAXIMUM LOAD | 12 tonne | 12 tonne |

| SPECIFICATIONS | PR600 | PR1350 |

| OVERALL WIDTH | 2650mm | 2650mm |

| OVERALL HEIGHT LOADING | 1650mm | 2250mm |

| OVERALL LENGTH | 8950mm | 8950mm |

| STANDARD TYRES | 400/60 x 15.5 Grips | 400/60 x 15.5 Grips |

| AXLE, HUBS & STUBS | Heavy Duty Tandem Oscillating 70mm | Heavy Duty Tandem Oscillating 70mm |

| TOWING EYE | 50mm Swivel | 50mm Swivel |

| HYDRAULICS (required with tilting elevator) | 2 pair double acting | 2 pair double acting |

| JOYSTICK | Electric | Electric |

| TARE WEIGHT | 4000kg | 4140kg |