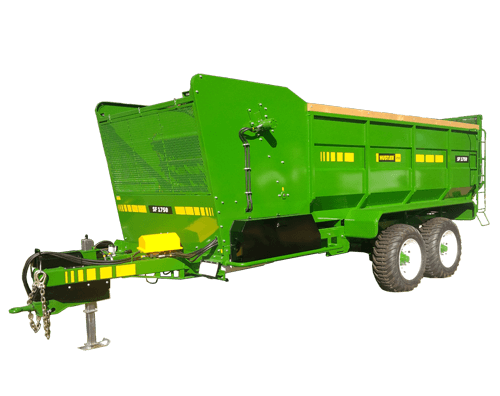

The Toughest 17.5m3 silage wagon on the market! For farmers who rely solely on silage as the supplementary feed of choice. Hustler’s silage wagons are built for large farmers and syndicates who simply cannot afford downtime and want to get the most production from their silage.

Benefits

- RELIABILITY – Built with an exceptionally strong chassis and frame design, all steel cross members and a strong heavy duty top rail. The main body and feeder section is fabricated of tough 3mm steel plate producing the strongest body. The heavy duty steel floor is fully welded to withstand any punishment eliminating the need to replace broken floor boards. The steel floor gives less resistance, reducing the power required to shift the load. The combination of a tough, well-proven design with the design smarts of such as the large delivery belt rollers that track straight eliminating belt derailing all developed to save you costly downtime, maintenance and extend the working life.

- EASY TO USE – Simple single lever control is all it takes to operate the machine. Elevator, conveyor and main floor with load-sensing hydraulics that takes the guesswork out of feeding silage.

- VERSATILITY – Choose centre feed for general pasture feeding with adjustable flaps which allows economical use with Sheep and Deer. The Side Feed model is ideal for trough feeding, feeding under a wire, feeding along a fence line to avoid trampling and general pasture feeding providing more versatility of use. The wide delivery belt to ensures an even unobstructed flow of material to best suit the variety of your silage feeding needs. You can also utilise this silage wagon to transport feed from the field to the stack when harvesting your crop.

- ACCURATE FEED DELIVERY – All Silage wagons now come load cell ready as standard, which allows you to add the weighing option when it suits your operation so you can accurately measure the correct amount your herd needs, reducing waste and increasing the performance of your farm. The unique loadcell design means the wagon can be a one-piece structure, rather than a separate chassis and body. This adds a large amount of strength to the machine.

Specifications

CAPACITY

Overall length: 8115mm

Overall width: 2780mm

Overall height: 2680mm

Loading height: 2440mm

Tare weight: 4150kg

Capacity: 17.2m3

SPECIFICATIONS

- Elevator/Conveyer: 900

- No. Floor chains: 4

- Jack type: 80 screw

- Axles size: 80 x 8

- Wheels: 340/65R18

- Floor type: Steel

Features

Single Hydraulic Control

The silage wagon only requires one hydraulic remote. Pull the lever to feed, our clever load-sensing hydraulics do the rest for you.

Load Cell Ready

All new comby wagons come weigh-scale ready from the factory, providing you with a future-proofed feeding solution and easy entry into the world’s best silage feeders. The unique design weighs the entire feeder, whether parked or on the tractor.

Largest Drive Roller On The Market

Extends the life of the conveyor belt, reduces drive slippage and downtime, and eliminate tricking adjustments to get the belt tracking straight.

Bumper Boards

Replaceable wooden hunger boards eliminate and damage from operator error when loading.

Steel Floor

With the all steel floor and sides, that lasts the lifetime of the feeder, you’ll never need to worry about a broken board breaking a chain, or rotting out from the exposure to silage juices. And the cleaner design of the single pressed sides reduce friction and load on the drives.

Covered Shafts

Heavy duty drives shafts that are covered, so you never need to worry about wrapping.

HD Axles

The toughest axle design on the market by a country mile, giving total peace of mind, and eliminating any possibility of downtime.

Large Suspension Travel

The oscillation of the tandem axle allows for travelling over the most rugged terrain with ease.

Bumper Bars

Replacable bumpers are positioned at the conveyor, mudguards and drive system the wagon to protect the vital parts of a wagon from interruption your feeding season.

Access Ladder

Rear mounted for health & safety reasons, the rear mounted ladder provides easy access to the main bin.

Auto Releasing Tailgate

The safety release of the tailgate design eliminates damage from operator error.

Hose Holder

The built-in hose holder, keeps hoses neatly stored out of the dirt when unplugged from the tractor.

Load Sensing Hydraulics

Makes controlling the SF1750 ultra-simple, and are nicely protected from the weather, mud and other contaminants. Another built-in downtime saver.

Safety Chains

Standard the Silage Wagon comes with safety chains, for added operator safety both on and off the road.

Heavy Duty Jack

The tough 80mm screw jack with the largest support area, means the jack supports the machine better whilst loading. The jack is designed strong enough to be used as a quick hitch foot.

Welded Body

The fully welded body eliminates the need for bolts or rivets which, when subject to vibration or flex, can loosen.

Forged Towing Eye

The approved towing eye offers 360 degree rotation to protect your tractor and can be locked to simplify hooking up with a quick-hitch.

Mudguards

Standard the SF1250 is fitted with heavy duty mudguards with bumper bars to eliminate damage should the operator hit a gate post.

Protected Hoses

The hoses on the silage wagons are protected from chaffing, another downtime eliminator.

HD Drives

The simple but heavy duty drives require very minimal maintenance and handle the heaviest of loads. Our chain drive gives the reliability of a gearbox, without the additional cost and parts delay should it get damaged. We’ve also protected the drives with bumper bars.

What our customers are saying

“Over the years I have purchased 4 Robertson machines. They are the strongest, most reliable, hardest working machine around. With the capability of feeding out silage, round & square bales so it also saved us capital expenditure by eliminating the need to pur

Ged, Warrnambool (Australia), Feedout wagonGet your Hustler

Newsletter Signup

Get Out There, in Hustler Country episodes and the latest news